E-commerce applications

Solutions from Baumer hhs

Baumer hhs e-commerce solutions for pressure-sensitive adhesive (PSA) application on shipping boxes lead to efficient packaging processes.

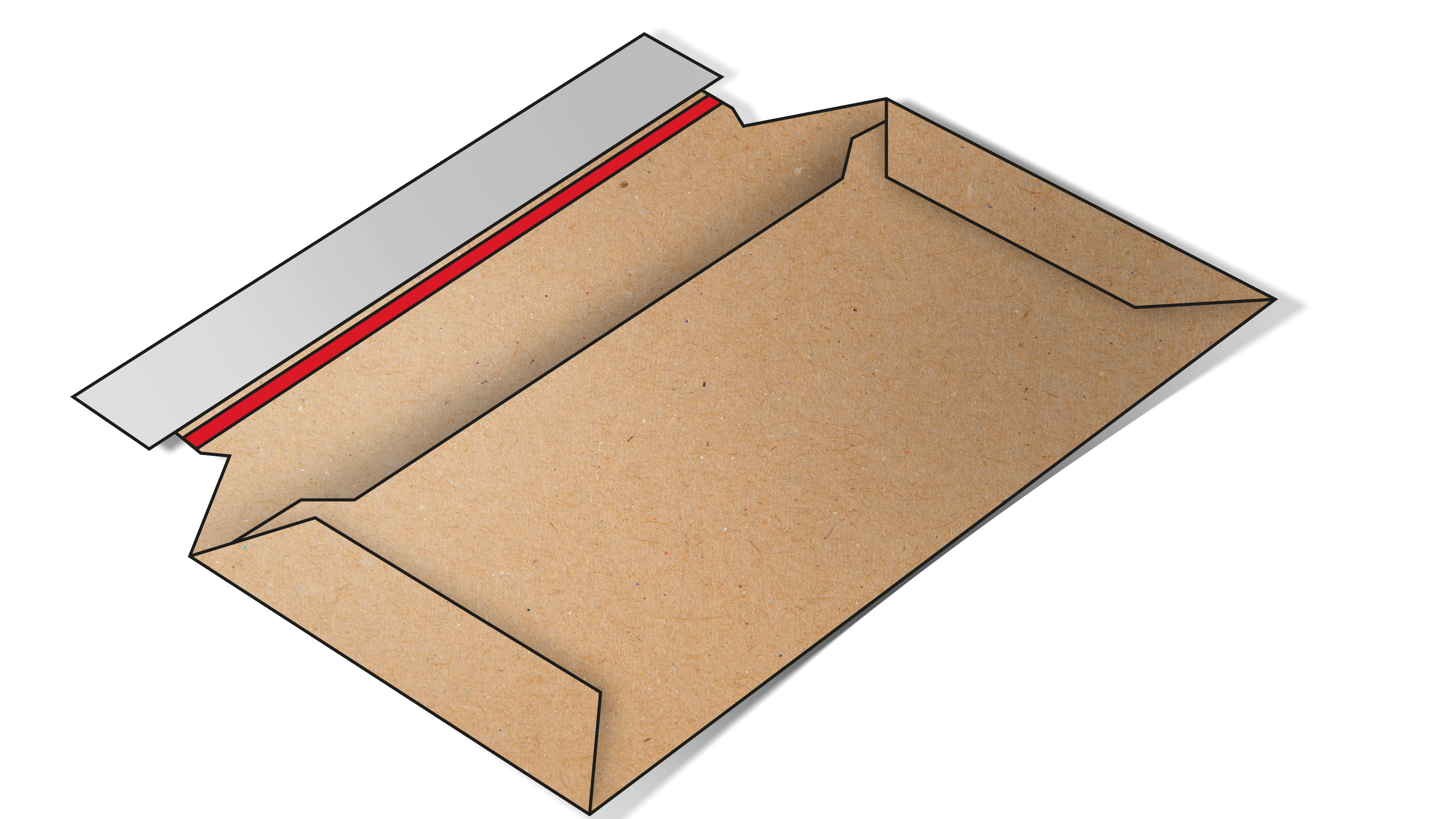

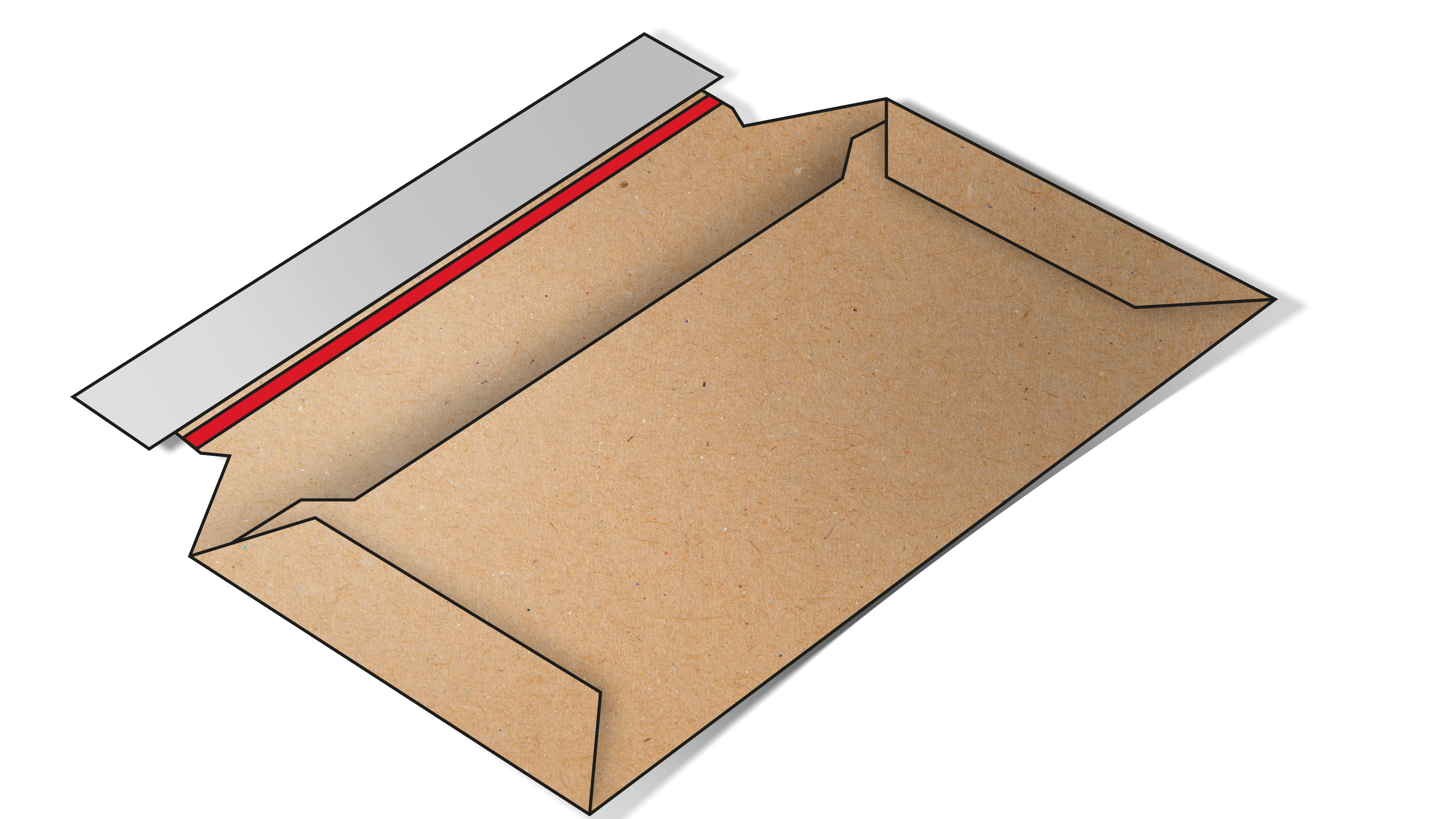

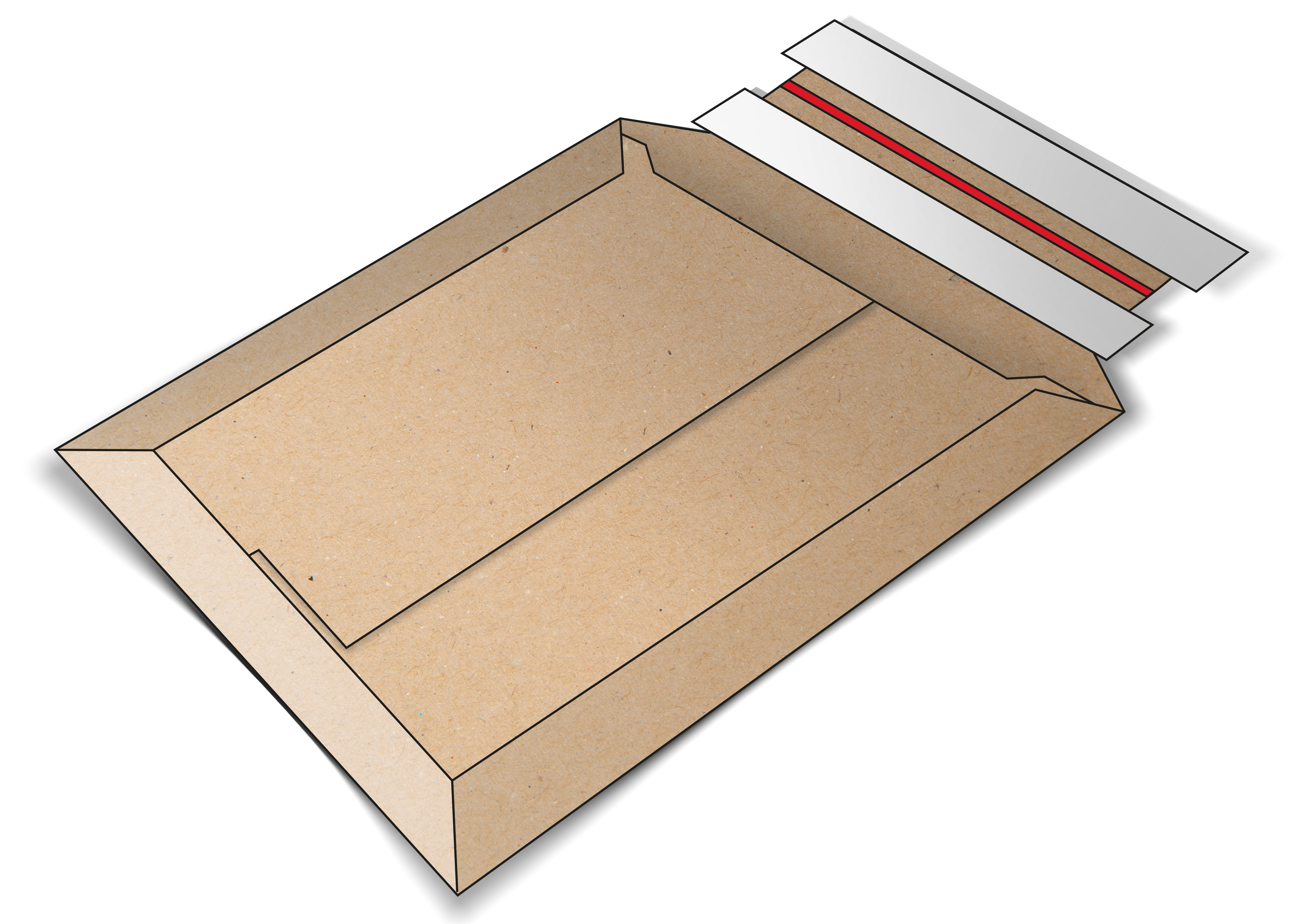

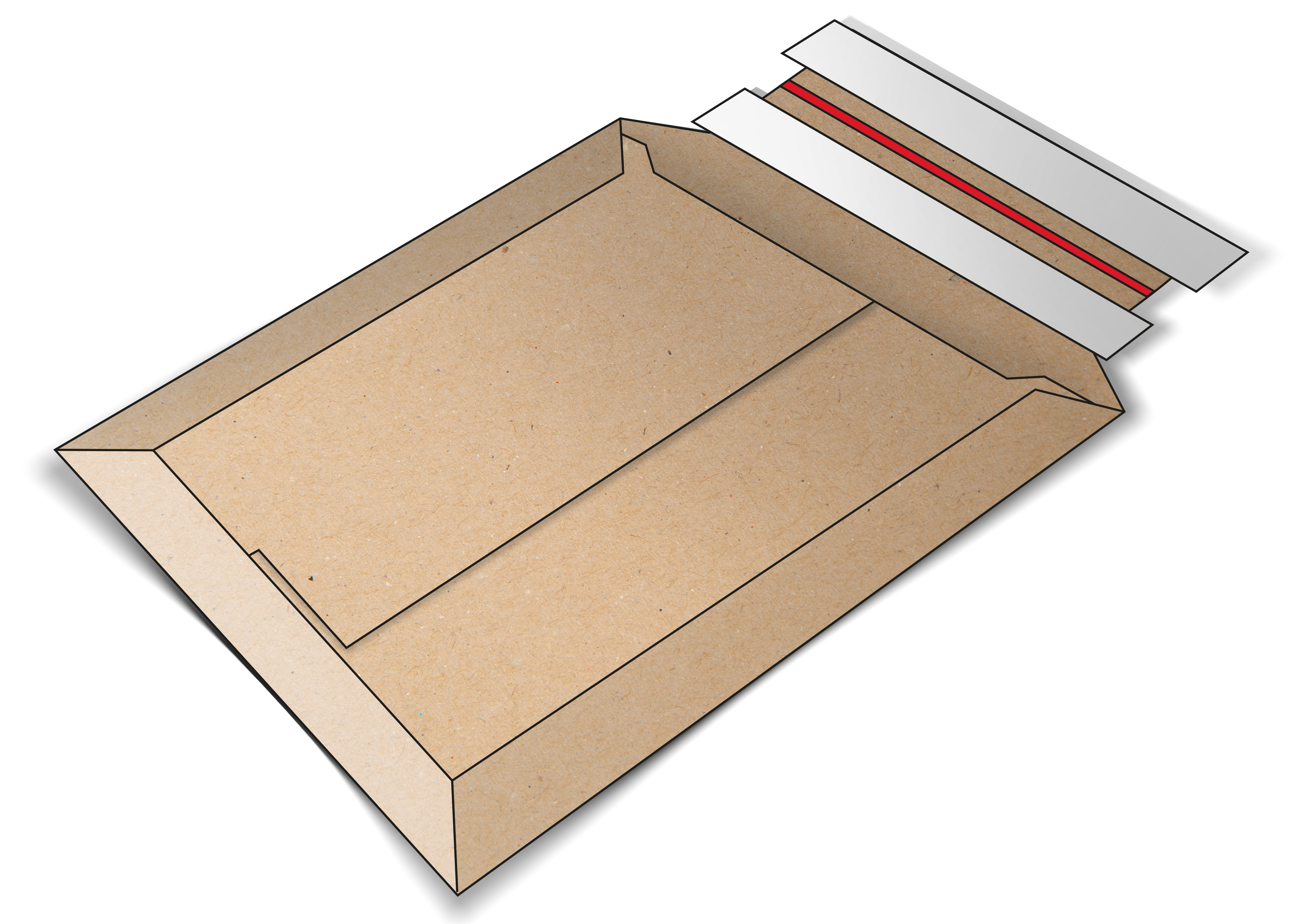

A pressure-sensitive adhesive strip that has already been applied to the substrate helps.

The silicone paper on the pressure-sensitive adhesive strip must be removed, the surfaces pressed together and the packaging is sealed.

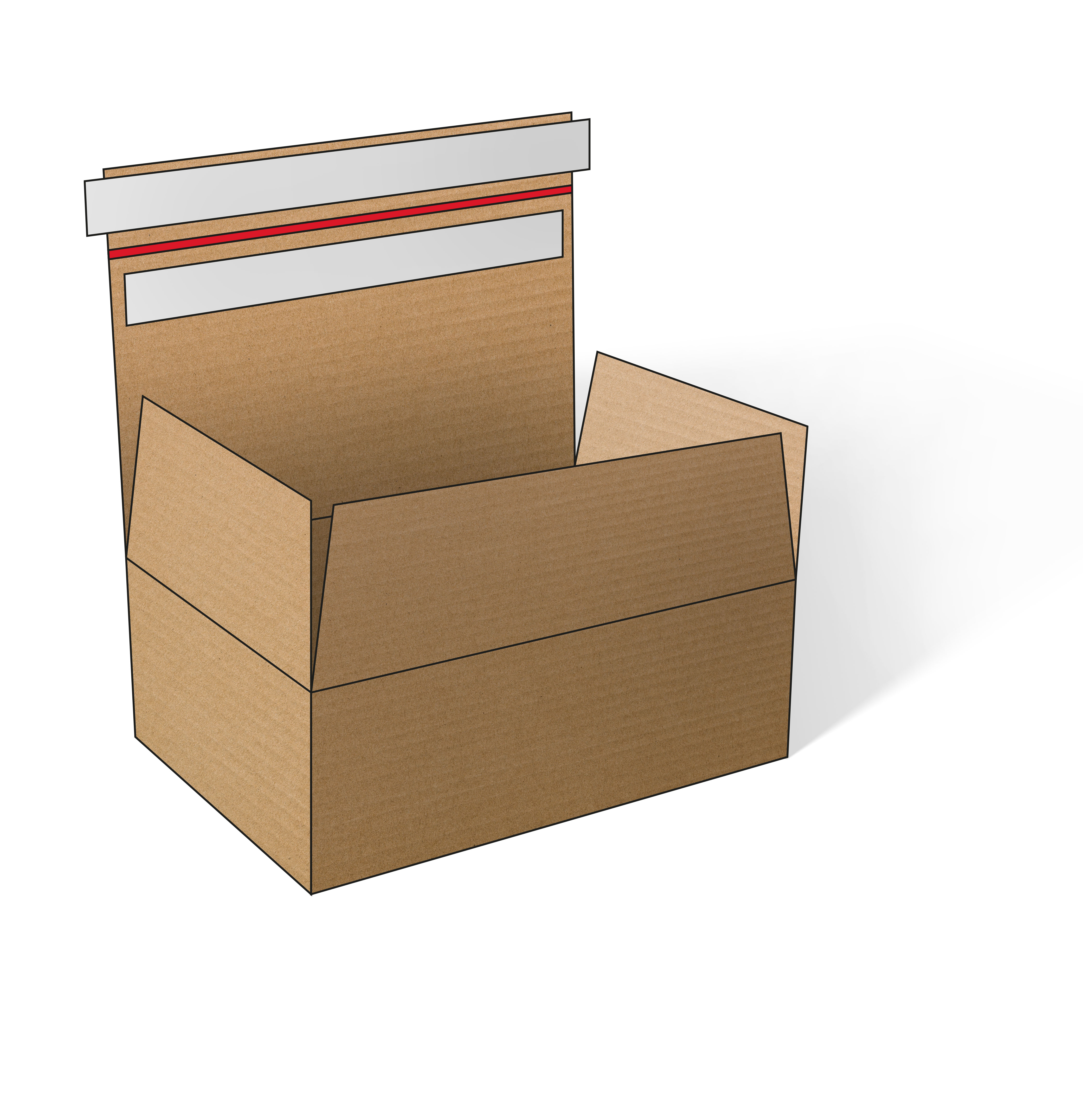

A second adhesive strip facilitates the return in the mail order business. The first adhesive strip is used to seal the packaging at the shipper's premises. The staff does not need adhesive tape, but simply and effectively pulls off a silicone strip and seals the packaging. The consumer can easily open the packaging with a tear-off strip without destroying the packaging. In case of a return, he can send the product back in the same packaging by resealing it with the second adhesive strip.

E-commerce packaging with adhesive strips therefore contributes significantly to a positive customer experience.

Baumer hhs is your Partner

for the fully automated application of pressure-sensitive adhesive strips on shipping packages made of paper, film, solid board and corrugated board.

The packets ensure excellent adhesive application

All complete packages are designed to be integrated directly.

Folding Carton machines

Packaging lines

Offline-machines

Shipping packaging made of paper and solid board

Folding carton board and paper substrates have a homogeneous, flat surface structure. The amount of pressure-sensitive adhesive (PSA) applied must be adapted to this. The required layer thicknesses are a maximum of 150g/sqm.

Solutions are offered for the application of one or two strips of pressure-sensitive adhesive.

The complete system optimised for this application comprises the HP-500-C contact application system and a 25kg melter.

- The HP-500 application head is characterised by the snuff-back principle. This principle creates a "negative pressure" that "pulls back" the material, so that an excellent cut-off is achieved and dripping of the material is prevented.

The complete system optimised for this application comprises the HP-500-C contact application system and a 25kg melter.

- The HP-500 application head is characterised by the snuff-back principle. This principle creates a "negative pressure" that "pulls back" the material, so that an excellent cut-off is achieved and dripping of the material is prevented.

Zur Anzeige des Klick-Modells nutzen Sie gerne unsere Desktop-Version.

The complete system optimised for this application comprises the HP-500-C contact application system and a 25kg melter.

- The HP-500 application head is characterised by the snuff-back principle. This principle creates a "negative pressure" that "pulls back" the material, so that an excellent cut-off is achieved and dripping of the material is prevented.

The complete system optimised for this application comprises the HP-500-C contact application system and a 25kg melter.

- The HP-500 application head is characterised by the snuff-back principle. This principle creates a "negative pressure" that "pulls back" the material, so that an excellent cut-off is achieved and dripping of the material is prevented.

Zur Anzeige des Klick-Modells nutzen Sie gerne unsere Desktop-Version.

Corrugated board shipping packaging

Based on a large number of worldwide installations and the experience gained with them, Baumer hhs offers a special adhesive application system for corrugated board shipping packaging.

Due to the unevenness of the corrugated board surface, adhesive application quantities of up to 500g/sqm are applied.

This adhesive application system is optimised for uniform adhesive application at high flow rates and quantities up to 500g/sqm.

- Contact Application System HM-500-C

- The Xmelt 100kg melter, with its single-cast tank design, efficiently melts large quantities of adhesive with a melting capacity of up to 120kg.

- Flow control based on optimised control algorithms ensures more consistent dispensing in relation to machine speeds.

This adhesive application system is optimised for uniform adhesive application at high flow rates and quantities up to 500g/sqm.

- Contact Application System HM-500-C

- The Xmelt 100kg melter, with its single-cast tank design, efficiently melts large quantities of adhesive with a melting capacity of up to 120kg.

- Flow control based on optimised control algorithms ensures more consistent dispensing in relation to machine speeds.

Zur Anzeige des Klick-Modells nutzen Sie gerne unsere Desktop-Version.

The packaging experience. The perfect solution for online trader.

Sustainability

Resource-efficient for increased sustainability

Fast set-up for perfect production start-up

Minimisation of cleaning cycles

No need for double-sided adhesive tape

Reuse of packaging for returnsAdhesive application optimised for the recycling process

Packaging dimensions adapted to product

Developed for greater reliability in production

No interruption of production

Perfect adhesive application

Insulation to avoid incidents of burns

Reliability