Folding carton applications

From the simple folding box to the complex six-pack

You can rely on it

Folding cartons are getting more complex all the time and no wonder, considering they have to support high-quality product presentation, protect what’s inside, serve as carriers and be as sustainable as possible. These multiple functions put growing demands on gluing and quality assurance systems. With its modular components, Baumer hhs offers a sophisticated and powerful system that meets even the highest of these technical demands: It is the industry benchmark.

Your applications Our solutions

Baumer hhs is your Partner

Our systems can be adapted to your individual needs. Benefit from our technology lead and Baumer hhs’s reputation for reliability.

Modularly designed for configuring complete gluing systems

Easily integrated in existing folder-gluers

OEM supplier to leading packaging machine manufacturers

Future-oriented and economical

For sustainable production

Everything from a single source

We make your team fit for tomorrow

Baumer hhs puts no limits on the possibilities open to its customers.

No matter what kind of products you have in mind, the systems from Baumer hhs for manufacturing folding cartons support a reliable process, even with the most complex products – and even at the highest required machine speeds.

Straight-line boxes

The straight-line box is the most common product in the folding carton industry. In most cases, high volumes of these boxes are produced at maximum machine speed. With Baumer hhs, you can rely on end-to-end monitoring of your production process. Product mix-ups and incorrectly glued joints are reliably identified and ejected.

The CT 300 verifies standard colour codes and compact pharmaceutical codes!

- 100% verification to prevent product mix-ups

- Ensures maximum process reliability in folding carton production

- High optical resolution

- Reduces code mark width by 50%

- Capable of monitoring colour on code marks measuring just 0.5mm

LNT 300 – Monitors the application of adhesive coatings using microwave technology!

- Monitors the volume applied across the entire glue flap

- Monitors product length using an integrated light barrier function

- Easy to operate while offering 100% process reliability in production

Product tracking through the machine and ejector control with the T&E module

- 100% process reliability in production - functions on the fail-safe principle

- Continuous production with maximum reliability

- Capable of controlling all common ejector types on the market

The CT 300 verifies standard colour codes and compact pharmaceutical codes!

- 100% verification to prevent product mix-ups

- Ensures maximum process reliability in folding carton production

- High optical resolution

- Reduces code mark width by 50%

- Capable of monitoring colour on code marks measuring just 0.5mm

LNT 300 – Monitors the application of adhesive coatings using microwave technology!

- Monitors the volume applied across the entire glue flap

- Monitors product length using an integrated light barrier function

- Easy to operate while offering 100% process reliability in production

Product tracking through the machine and ejector control with the T&E module

- 100% process reliability in production - functions on the fail-safe principle

- Continuous production with maximum reliability

- Capable of controlling all common ejector types on the market

Zur Anzeige des Klick-Modells nutzen Sie gerne unsere Desktop-Version.

Crash-lock bottom boxes with

hot melt and cold glue

Folding carton-style premium packaging with sophisticated finishes. Precision gluing on the bottom flap prevents inside gluing, eliminating problems erecting the boxes in the packaging line before they occur.

LNT 300 – Monitors the application of adhesive coatings using microwave technology!

- Monitors the volume applied across the entire glue flap

- Monitors product length using an integrated light barrier function

- Easy to operate while offering 100% process reliability in production

Xcam – Monitors adhesive application and diagonal creasing!

Line scan cameras combined with UV or white LED linear lighting.

- Monitors adhesive application

- Detects glue-free areas

- Detects flaps

- Verifies creasing of the bottom flaps

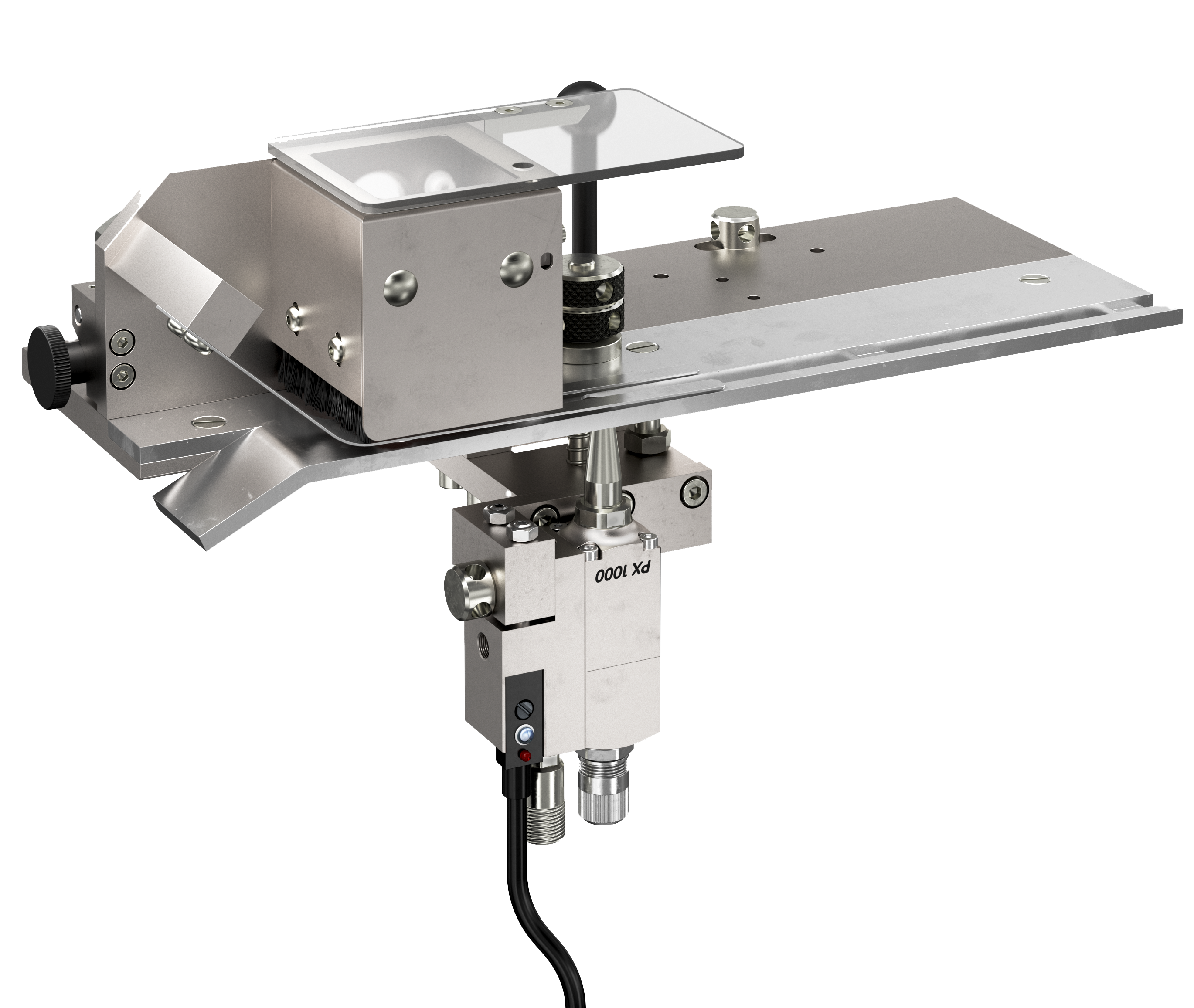

PX 1000 – The application head for precision gluing at maximum production speed!

- High closing force for minimal tailing and precision restart

- Reduced contamination means longer cleaning intervals and maximum productivity

- Processes a wide range of adhesive viscosities

- Maximum service life

- High process reliability in production

GDX 1000 – The optical sensor for monitoring glue application at maximum production speed!

- Monitors glue application 100%

- Monitors glue-free areas

- Integrated light barrier function for monitoring product length

- Sensor can be set up at the Xtend³ controller

The CT 300 verifies standard colour codes and compact pharmaceutical codes!

- 100% verification to prevent product mix-ups

- Ensures maximum process reliability in folding carton production

- High optical resolution

- Reduces code mark width by 50%

- Capable of monitoring colour on code marks measuring just 0.5mm

LNT 300 – Monitors the application of adhesive coatings using microwave technology!

- Monitors the volume applied across the entire glue flap

- Monitors product length using an integrated light barrier function

- Easy to operate while offering 100% process reliability in production

Xcam – Monitors adhesive application and diagonal creasing!

Line scan cameras combined with UV or white LED linear lighting.

- Monitors adhesive application

- Detects glue-free areas

- Detects flaps

- Verifies creasing of the bottom flaps

PX 1000 – The application head for precision gluing at maximum production speed!

- High closing force for minimal tailing and precision restart

- Reduced contamination means longer cleaning intervals and maximum productivity

- Processes a wide range of adhesive viscosities

- Maximum service life

- High process reliability in production

GDX 1000 – The optical sensor for monitoring glue application at maximum production speed!

- Monitors glue application 100%

- Monitors glue-free areas

- Integrated light barrier function for monitoring product length

- Sensor can be set up at the Xtend³ controller

The CT 300 verifies standard colour codes and compact pharmaceutical codes!

- 100% verification to prevent product mix-ups

- Ensures maximum process reliability in folding carton production

- High optical resolution

- Reduces code mark width by 50%

- Capable of monitoring colour on code marks measuring just 0.5mm

Zur Anzeige des Klick-Modells nutzen Sie gerne unsere Desktop-Version.

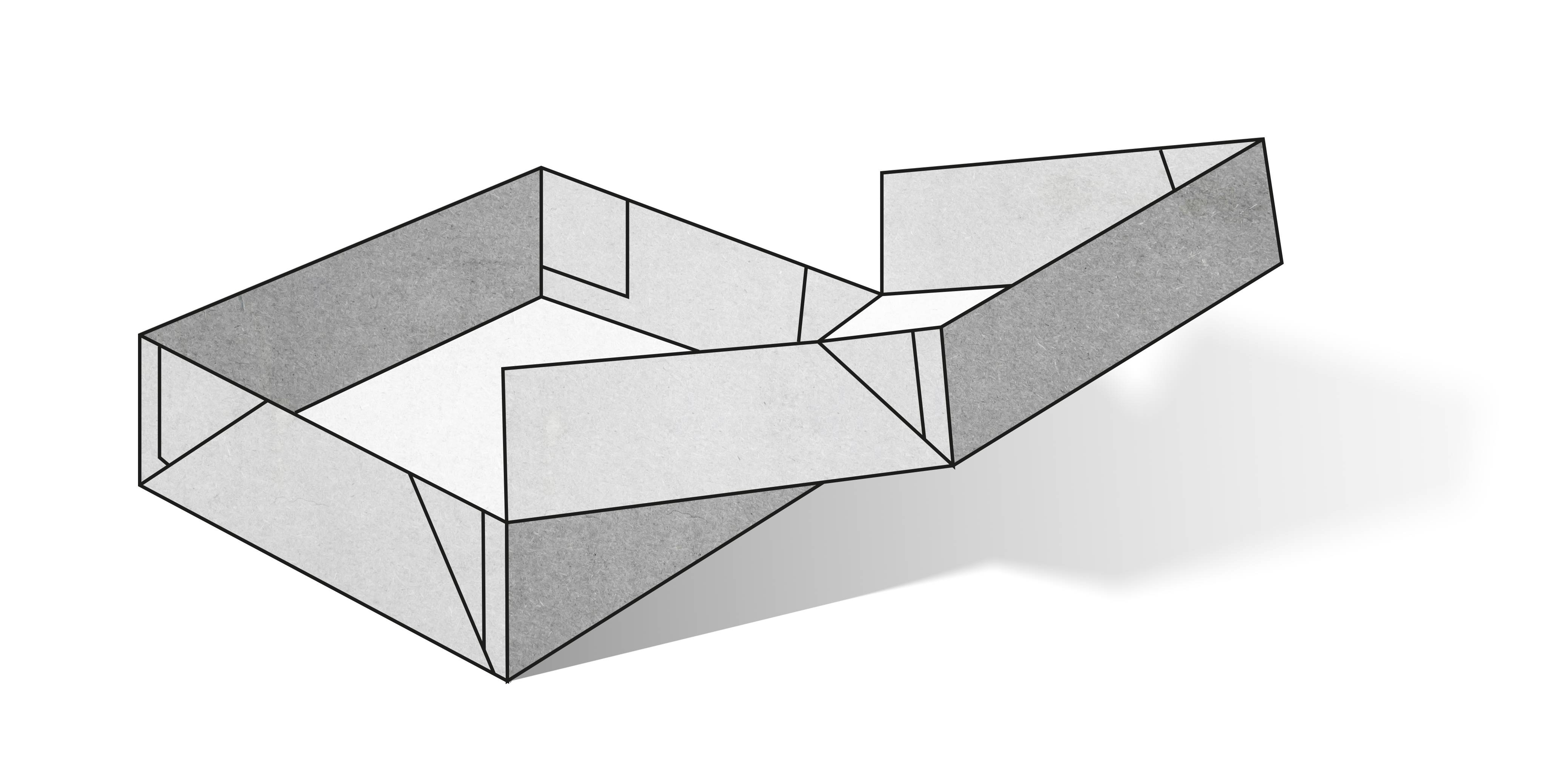

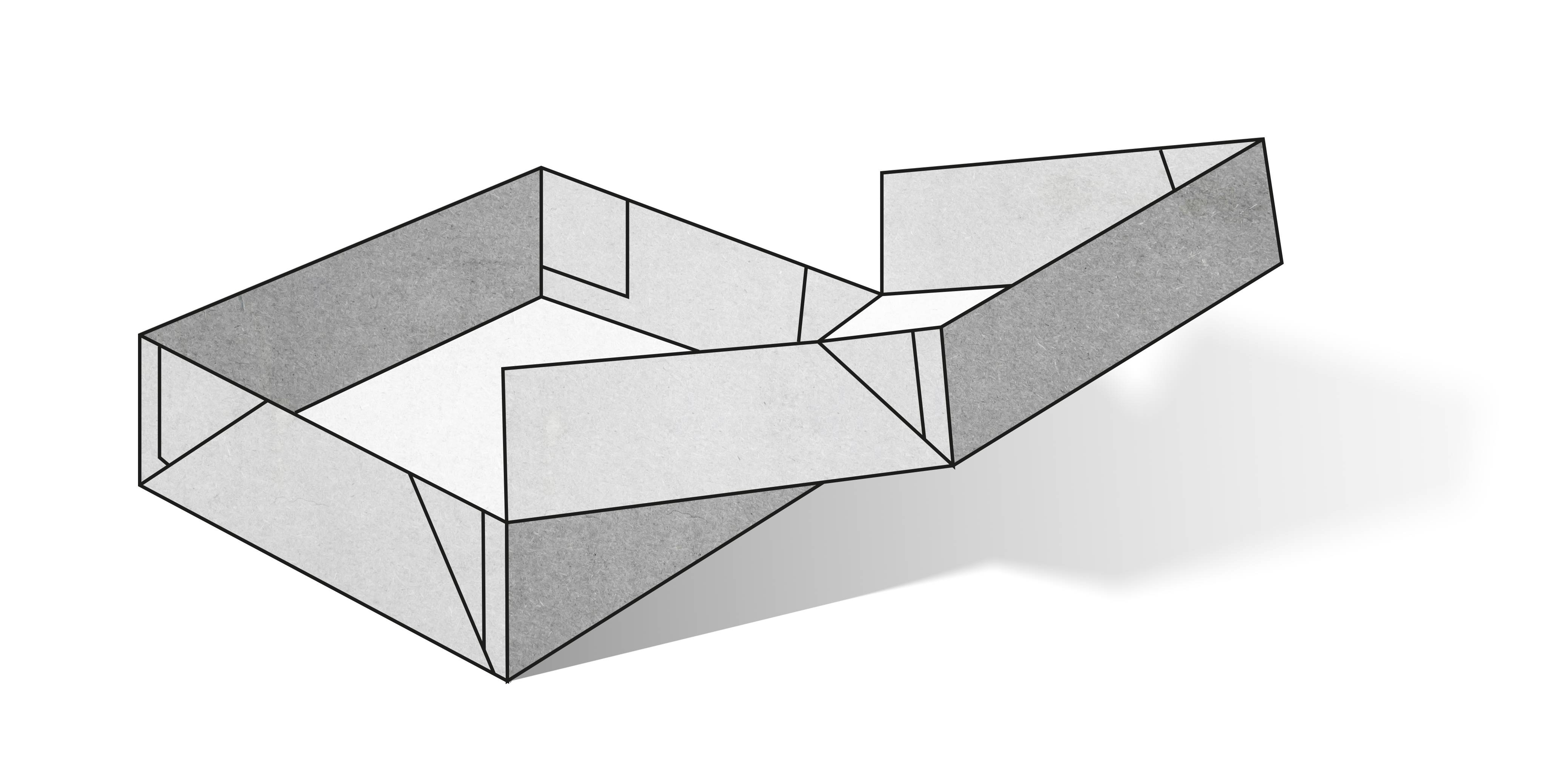

4- and 6-corner folding cartons

These popular folding cartons for food and consumer products, such as baked goods, sweets, fruit and vegetables, are precision-manufactured at high speed. The glue must be applied with maximum precision even on small flaps. The Xcam verifies that all flaps are precisely folded.

The CT 300 verifies standard colour codes and compact pharmaceutical codes!

- 100% verification to prevent product mix-ups

- Ensures maximum process reliability in folding carton production

- High optical resolution makes it possible to reduce code mark width by 50%

- Capable of monitoring colour on code marks measuring just 0.5mm

PX 1000 – The application head for precision gluing at maximum production speed!

- High closing force for minimal tailing and precision restart

- Reduced contamination means longer cleaning intervals and maximum productivity

- Processes a wide range of adhesive viscosities

- Maximum service life

- High process reliability in production

GDX 1000 – The optical sensor for monitoring glue nozzle application at maximum production speed!

- Monitors glue application 100%

- Monitors glue-free areas

- Integrated light barrier function for monitoring product length

- Sensor can be set up on the screen of the Xtend³ controller

Xcam – Monitors adhesive application and diagonal creasing!

Line scan cameras combined with UV or white LED linear lighting.

- Monitors adhesive application

- Detects glue-free areas

- Detects flaps

- Verifies diagonal creasing of the bottom flaps

The T&E module tracks products through the machine and automatically ejects them!

- 100% process reliability in production - functions on the fail-safe principle

- Ensures continuous production flows and maximum process reliability

- Capable of controlling all ejector types

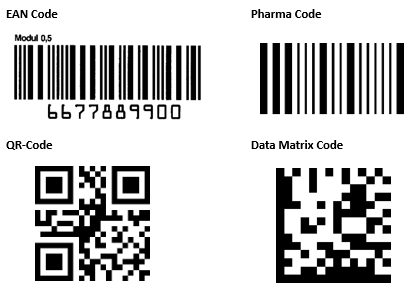

Scan 300 – Laser scanner for detecting all common EAN codes!

- Examples: Code 128 / 2/5 Interleaved / Code 39

- 100% production control to prevent product mix-ups

The CT 300 verifies standard colour codes and compact pharmaceutical codes!

- 100% verification to prevent product mix-ups

- Ensures maximum process reliability in folding carton production

- High optical resolution makes it possible to reduce code mark width by 50%

- Capable of monitoring colour on code marks measuring just 0.5mm

PX 1000 – The application head for precision gluing at maximum production speed!

- High closing force for minimal tailing and precision restart

- Reduced contamination means longer cleaning intervals and maximum productivity

- Processes a wide range of adhesive viscosities

- Maximum service life

- High process reliability in production

GDX 1000 – The optical sensor for monitoring glue nozzle application at maximum production speed!

- Monitors glue application 100%

- Monitors glue-free areas

- Integrated light barrier function for monitoring product length

- Sensor can be set up on the screen of the Xtend³ controller

Xcam – Monitors adhesive application and diagonal creasing!

Line scan cameras combined with UV or white LED linear lighting.

- Monitors adhesive application

- Detects glue-free areas

- Detects flaps

- Verifies diagonal creasing of the bottom flaps

The T&E module tracks products through the machine and automatically ejects them!

- 100% process reliability in production - functions on the fail-safe principle

- Ensures continuous production flows and maximum process reliability

- Capable of controlling all ejector types

Scan 300 – Laser scanner for detecting all common EAN codes!

- Examples: Code 128 / 2/5 Interleaved / Code 39

- 100% production control to prevent product mix-ups

Zur Anzeige des Klick-Modells nutzen Sie gerne unsere Desktop-Version.

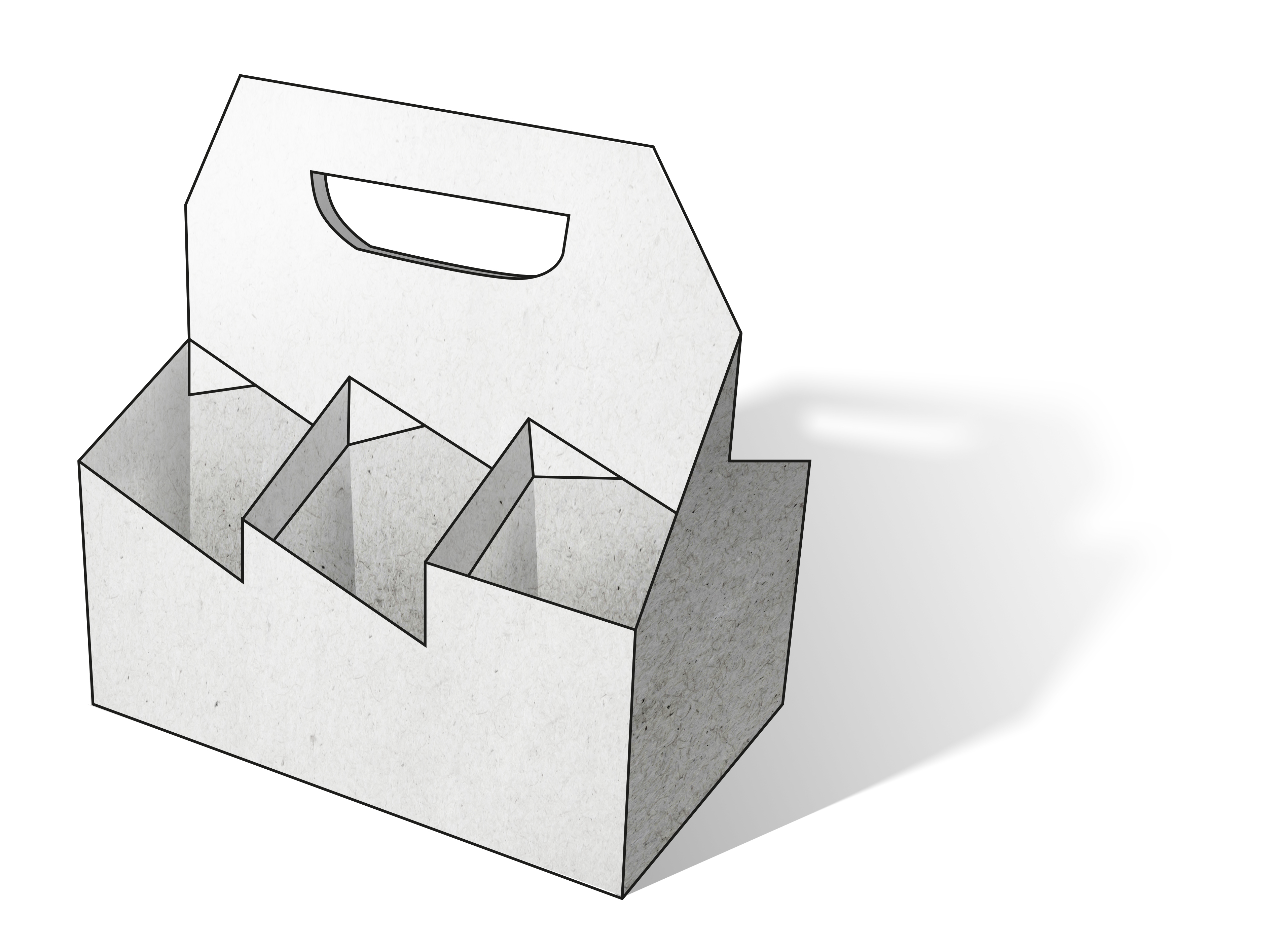

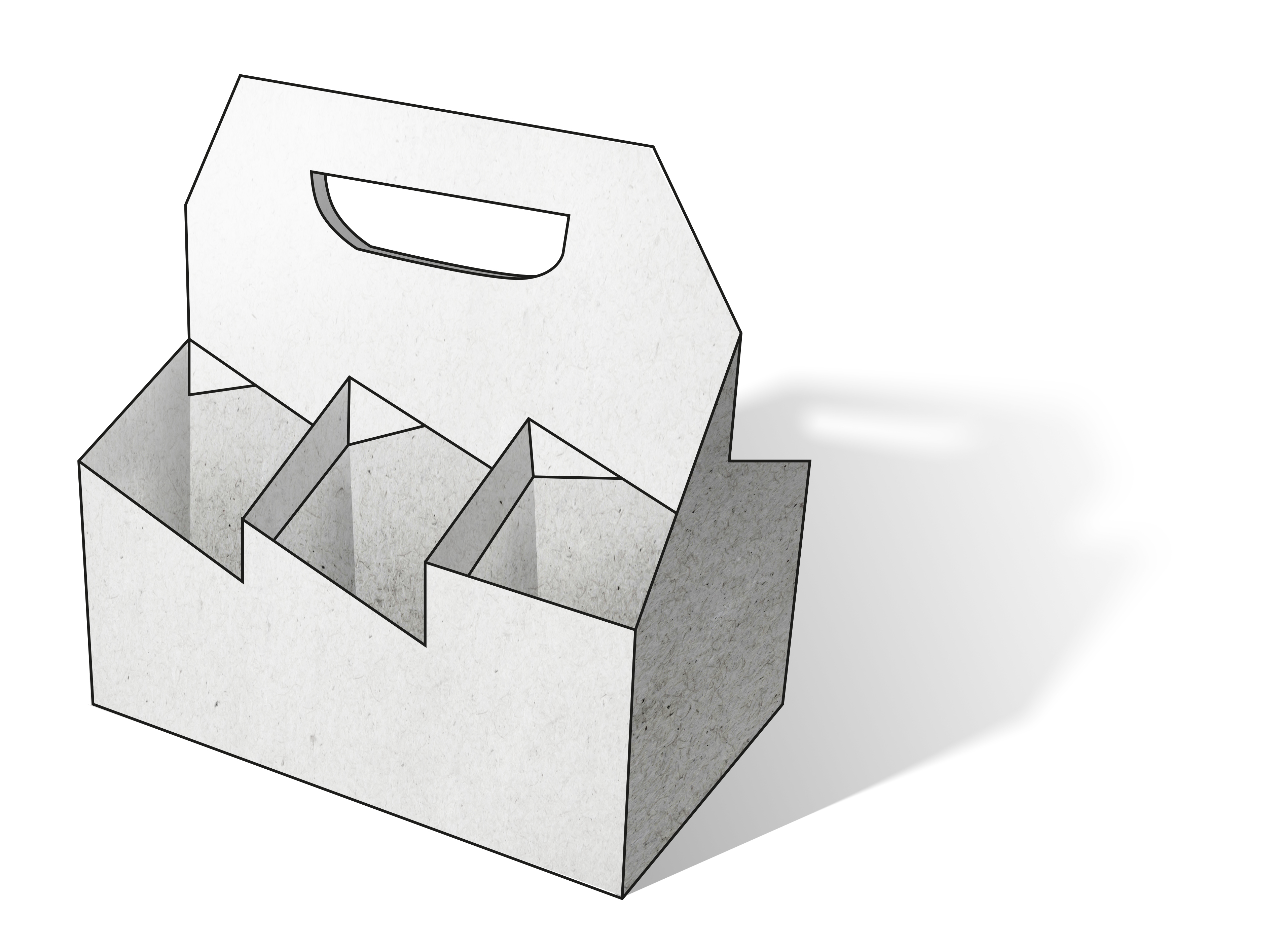

Six-packs and special designs

Six-packs and other special designs put complex demands on gluing. For example, the adhesive may have to be applied by 16 or more application heads at several stations in a single folder-gluer.

High-tech folding mechanisms require precision dot application as well as monitoring equipment capable of reliably detecting even the smallest deviations. The Xcam camera equipment monitors all glue tracks and prevents the risk of inside gluing. Baumer hhs systems solve problems you have yet to encounter.

PX 1000 – The application head for precision gluing at maximum production speed!

- High closing force for minimal tailing and precision restart

- Reduced contamination means longer cleaning intervals and maximum productivity

- Processes a wide range of adhesive viscosities

- Maximum service life

- High process reliability in production

Scan 300 – Laser scanner for detecting all common EAN codes!

- Examples: Code 128 / 2/5 Interleaved / Code 39

- 100% production control to prevent product mix-ups

The T&E module tracks products through the machine and automatically ejects them!

- 100% process reliability in production - functions on the fail-safe principle

- Ensures continuous production flows and maximum process reliability

- Capable of controlling all ejector types

PX 1000 – The application head for precision gluing at maximum production speed!

- High closing force for minimal tailing and precision restart

- Reduced contamination means longer cleaning intervals and maximum productivity

- Processes a wide range of adhesive viscosities

- Maximum service life

- High process reliability in production

Scan 300 – Laser scanner for detecting all common EAN codes!

- Examples: Code 128 / 2/5 Interleaved / Code 39

- 100% production control to prevent product mix-ups

The T&E module tracks products through the machine and automatically ejects them!

- 100% process reliability in production - functions on the fail-safe principle

- Ensures continuous production flows and maximum process reliability

- Capable of controlling all ejector types

Zur Anzeige des Klick-Modells nutzen Sie gerne unsere Desktop-Version.

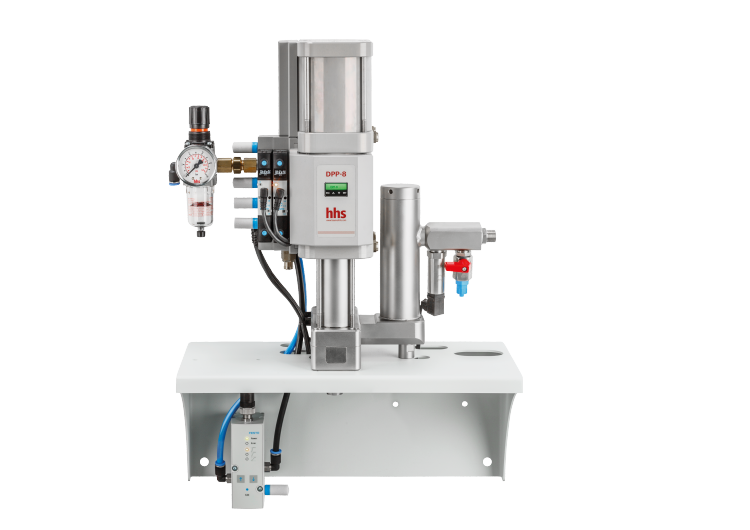

Side Seam Gluing Solution

Traditionally, in folding carton production the glue is applied to the glue flap with a wheel applicator. The problems associated with this process, such as cleaning and waste have been accepted by the industry for lack of alternatives.

Side Seam Gluing Solution from Baumer hhs now replaces existing disk gluing units and offers numerous associated advantages.

Xcheck DCM

The modern Xcheck DCM camera system monitors the feeder of the die cutter and thus closes an existing gap in quality monitoring. Inspection in the die cutter offers many advantages. For example, under-mixing of die-cut sheets is detected. The early detection of under-mixing in the process ensures less downtime and increases your productivity

- Simple integration

- Detection of 1D and 2D codes

- 100% quality control of all punched sheets

- For the front and back of the sheet

- Ready for future quality control requirements

Sustainability

Resource-efficient for increased sustainability

Fast setup for perfect production startup

Minimises cleaning cycles

Reduces production downtime by means of quality assurance and product tracking

Dot application reduces glue consumption

Developed for greater reliability in production

Fail-safe principle

100% quality control

Perfect adhesive application

Production data networking and analysis

Reliability

Folding Carton Production - See for yourself!