Seamless monitoring of production is essential to ensure product quality.

Baumer hhs Xcheck sensor and camera solutions are an elementary part of quality assurance in packaging production.

In many applications, Baumer hhs QA products have long been the international standard.

100% quality with Xcheck!

Xcheck Cold glue detection

Cold glue detection in perfection.

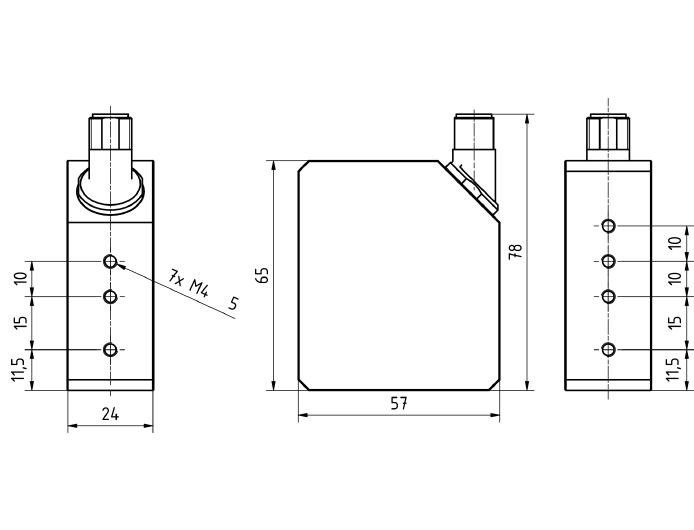

With the completely newly developed GDX 1000 adhesive sensor, based on thousands of installations, Baumer hhs provides its customers with the right quality assurance tool for future requirements.

Take your production to the next level.

- Reduced set-up times

- Early detection of emerging defects

- Reliable monitoring of adhesive-free areas

- Easy set up

- Set up and check the sensor on the control unit

- Scanning frequency 20kHz

Technical Data

| Specification | Value | Unit |

|---|---|---|

| Operating voltage | 24 +- 20% | VDC |

| Power consumption, maximum | 150 | mA |

| Measurement principle | Infrared measurement | - |

| Scanning frequency | 20 | kHz |

| 50 | µs | |

| Minimum monitorable dot size | 1 x 1 | mm |

| Spot size | 5 x 1,6 | mm |

| Measuring distance to product | 25 +- 5 | mm |

Especially for use with multipoint gluers

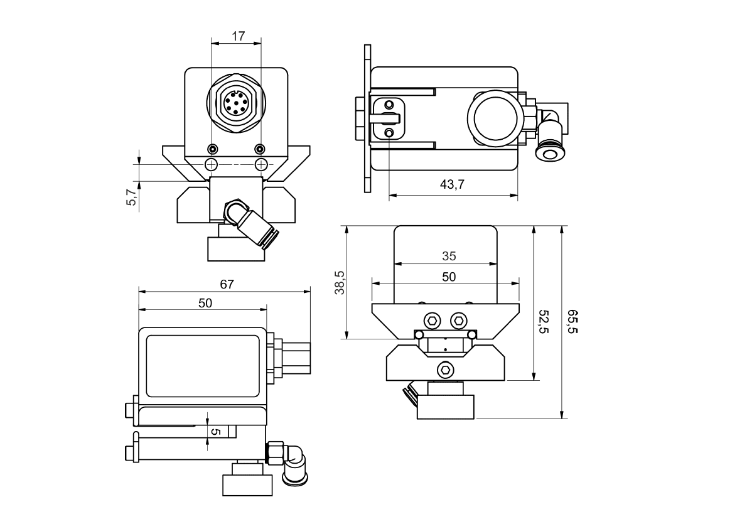

The ULT 400 XL is specially designed for use in multipoint gluers.

The specially developed optics allow a greater distance to the product. This is particularly advantageous with thicker cardboard and corrugated board.

- Measuring distance 62.5 ± 12.5 mm

A Sensor, but camera like

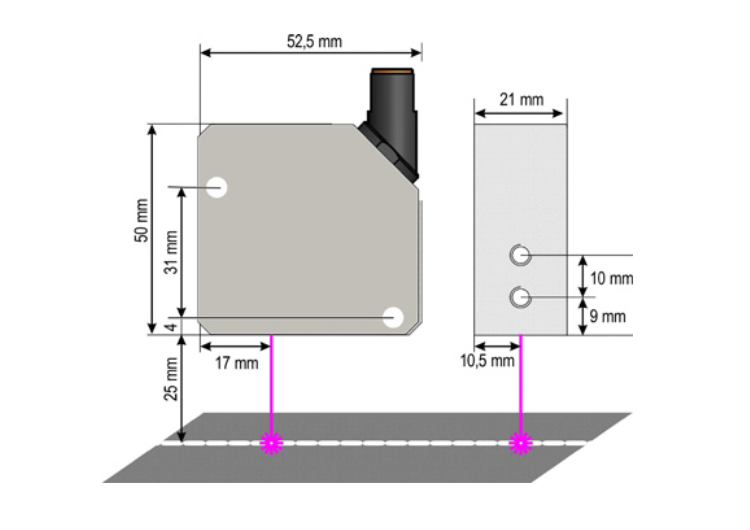

The PGD 1000 is the new benchmark in glue detection for corrugated production.

Designed for the upcoming challenges of the industry.

- 100% detection of cold glue

- No optical brighteners are needed in the adhesive

- Regardless of whether the substrate is printed or not

Technical Data

| Specification | Value | Unit |

|---|---|---|

| Operating voltage | 24 ± 20 % | VDC |

| Power consumption maximum | 150 | mA |

| Measuring principle | Infrared measurement | - |

| Scanning frequency | 10 | kHz |

| Minimum dot size | 1x1 | mm |

| Viewing widht | ~ 55 | mm |

| Measurement distance to product | 25 ± 5 | mm |

| Protection class | IP 64 |

Cold glue detection on metallised substrate

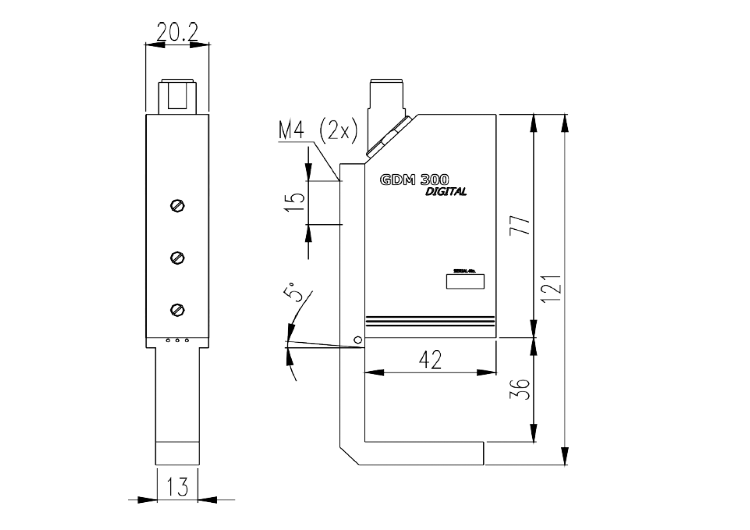

Finishing is all around us in folding carton production. The GDM-300 is specially designed for adhesive detection on metallised board surfaces.

- Special application

- Foil finishing

- Precise adhesive detection

Technical Data

| Specification | Value | UNit |

|---|---|---|

| Operating voltage | 10 - 30 | V |

| Power consumption 12 V | 200 | mA |

| Power consumption 24 V | 100 | mA |

| Spot size | 8 | mm |

| Measuring distance to product | 25 ± 5 | mm |

| Scanning frequency | 10 | kHz |

| Protection class | 64 | IP |

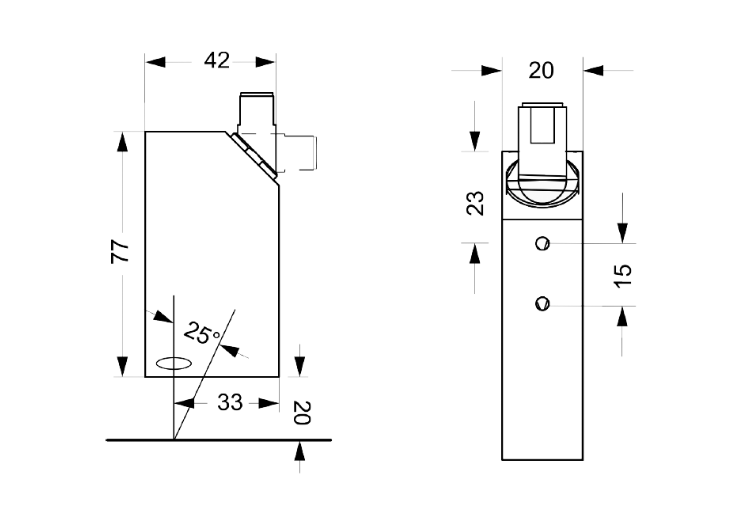

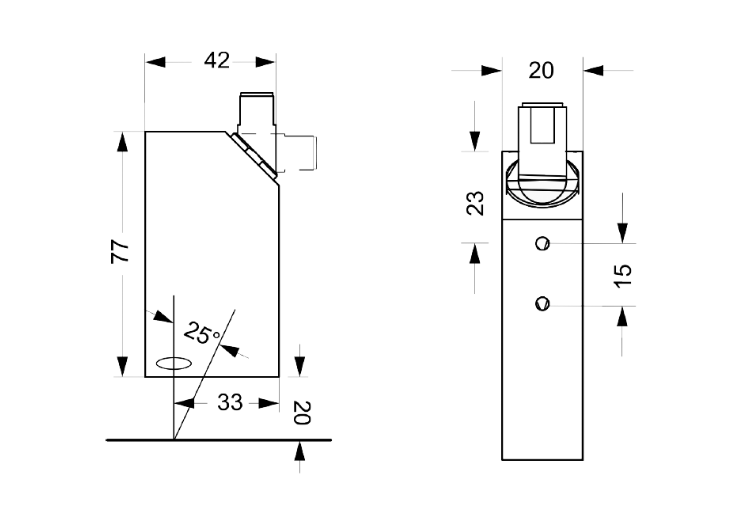

Checking disc glue application

With the LNT-300, Baumer hhs provides all users of disc gluing systems with a reliable solution for inspection.

The sensor reliably detects the adhesive and is thus part of the quality monitoring in straightline production.

- Easy set up

- Reliable at all machine speeds

- Adjustable via Baumer hhs control units

Xcheck Hot melt detection

Reliable detection. Dot for dot!

With the HLT-300 you can detect every adhesive dot. Wherever hot glue is applied, monitoring is important. The HLT-300 detects not only the presence, but also whether the adhesive is still hot enough to ensure reliable bonding.

- Reliable hot-melt detection

- For dot and line application

- Evaluation in the sensor

Technical Data

| Specification | Value | Unit |

|---|---|---|

| Operating voltage | 10 - 30 | V |

| Power consumption 12 V | 200 | mA |

| Power consumption 24 V | 100 | mA |

| Minimal dot size | 1x1 | mm |

| Spot size | 8 x 2 | mm |

| Measuring distance to product | 20 ± 5 | mm |

| Scanning frequency | 10 | kHz |

| Protection class | 64 | IP |

| Temperature range | 10 - 40 | °C |

| Relative humidity max. | 70 | % |

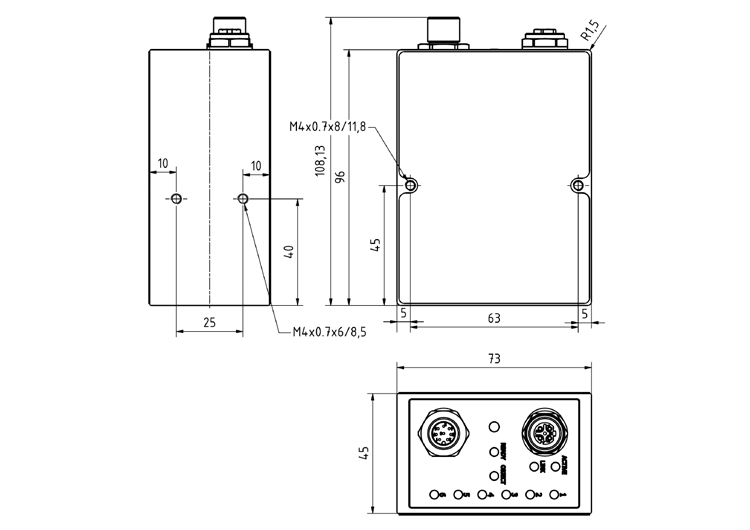

Hot melt detection for evaluation on a PLC

In packaging production, the use of hot-melt for closing folding boxes is standard. For this application, the HLT-300 was also developed in a version that can be evaluated directly at a PLC machine control.

This makes it possible to monitor the glue application in this application as well.

- Reliable hot melt detection

- For dot application and line application

- Evaluation in the sensor

Technical Data

| Specification | Value | Unit |

|---|---|---|

| Operating voltage | 10 - 30 | V |

| Power consumption 12 V | 200 | mA |

| Power consumption 24 V | 100 | mA |

| Minimal dot size | 1x1 | mm |

| Spot size | 8 x 2 | mm |

| Measuring distance to product | 20 ± 5 | mm |

| Scanning frequency | 10 | kHz |

| Protection class | 64 | IP |

| Temperature range | 10 - 40 | °C |

| Relative humidity max. | 70 | % |

Available with impulse length: 0, 5, 10, 15 ms

Xcheck Codereading

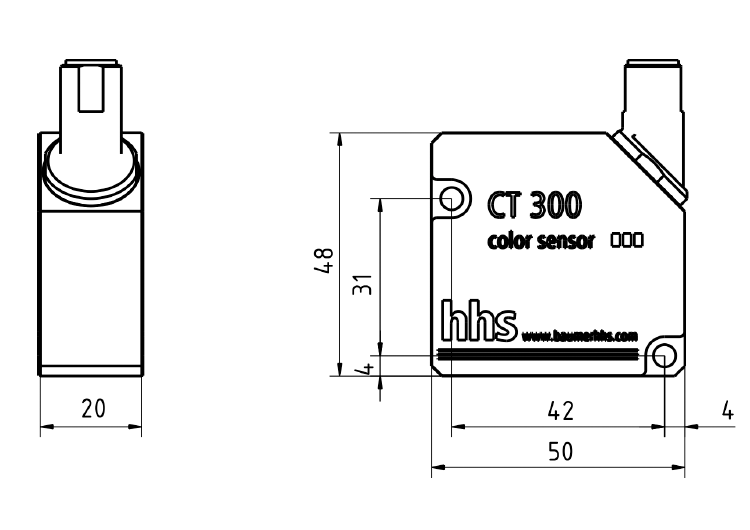

Detection of coloured barcodes

Glue flaps are provided with barcodes for anti-mix control. The CT-300 is not only able to read single-colour codes, but also coloured codes.

With its high resolution, it enables the use of small codes. This means that coding on very small flaps is also possible.

- Colour code recognition

- High resolution

- Code lengths from 19 mm

Technical Data

| Specification | Value | Unit |

|---|---|---|

| Operating voltage | 200 | mA |

| Power consumption | 24 | V |

| Scanning frequency | 33 | kHz |

| Protection class | 54 | IP |

| Temperature range | 10 - 45 | °C |

| Spot size | 0,4 x 2 | mm |

| Distance | 19 | mm |

Read barcodes safely

Different barcodes are used at many points in the production of packaging. The evaluation of the codes is essential for error-free production.

With the SCAN 400 you are always on the safe side.

With the Auto-Function in Xtend³ the code will be automatically selected.

Code Types:

- Code 39

- Interleaved 2/5

- Code 128

- Interleaved 2/5 ECC

- EAN-8

- Pharmacode

- EAN-13

| Specification | Value | Unit |

|---|---|---|

| Operating voltage | 5 | V |

| Power consumption max. | 2,6 | W |

| Protection class | 54 | IP |

| Laser class EU | 2 | |

| Wavelength | 650 | nm |

| Light energy max. | <1 | mW |

| Temperature range | 10 - 40 | °C |