Print finishing applications

Perfect solutions for all requirements

Complexity

The reliability and success of your product print runs depend largely on two factors: precise adhesive application head function and seamless monitoring. Only the fault-free interaction of both functions guarantees productivity and quality. From feeder to display.

Baumer hhs as your partner

Our systems adapt to your individual requirements. Enjoy the benefits of our technological edge and signature Baumer hhs reliability.

For sustainable production

The widest range of applications with maximum product quality and speed

Minimal set-up, maintenance and cleaning effort

Simple integration – even in existing systems

No impairment of speed and sheet travel

Autonomous and integrated quality assurance systems

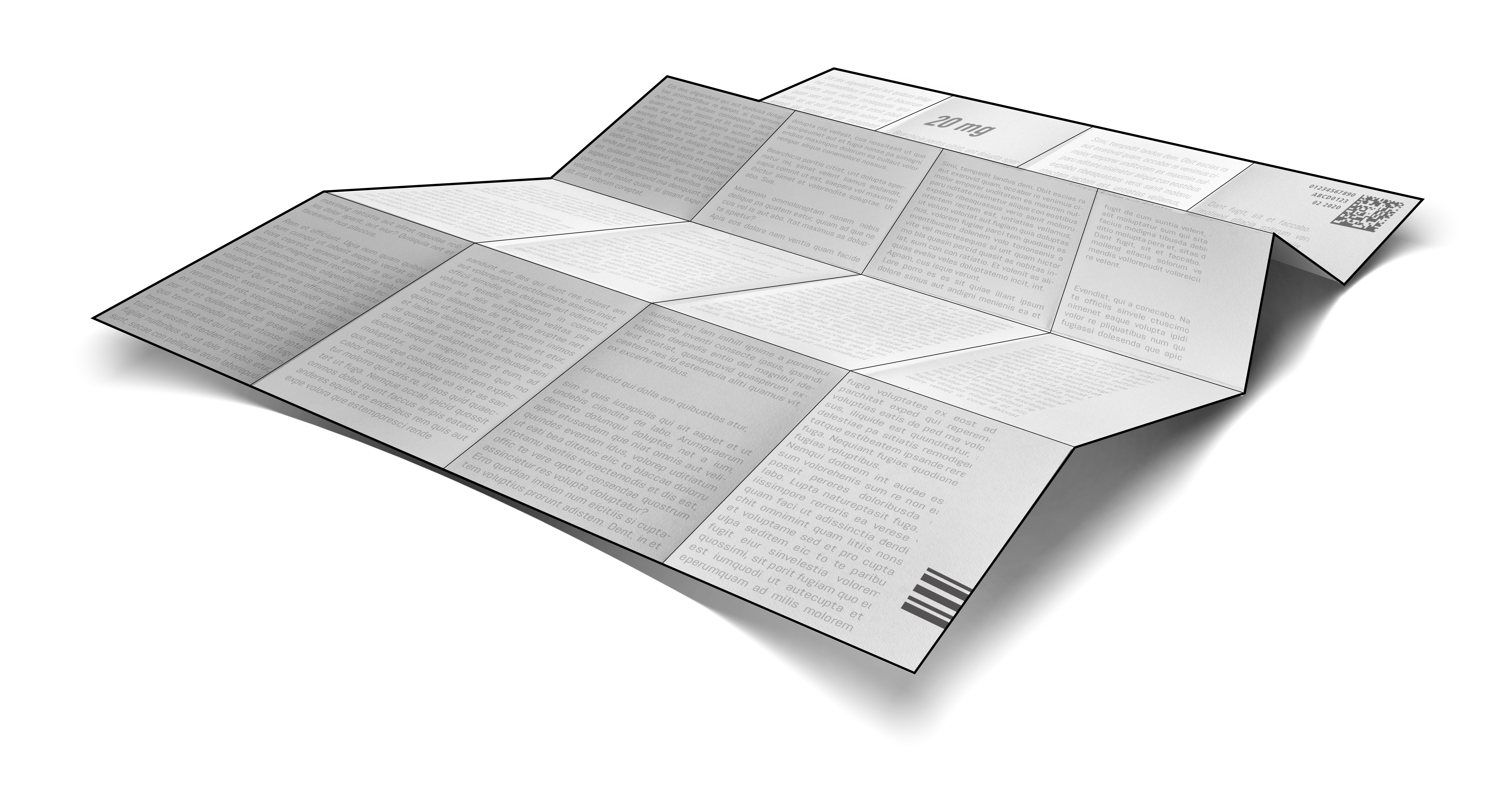

Package insert

Go to your doctor or pharmacist and read a package insert. This will prove how important having the right package insert in the right packaging can be: vital. In the production of packaging and package inserts for the pharmaceutical industry, errors simply cannot be made. Baumer hhs offers the perfect systems for anti mix up in your sheet folders and outsert systems.

When checking blank sheets, a black and white contrast comparison is used to check whether double-sided printing has taken place. This is a reliable means of detecting whether there are missing or blank sheets in the stack. These are reliably ejected.

The Xtend3 camera verification performs flawless 1D / 2D code detection and reliably detects all common code formats such as EAN, Pharma, Interleaved, QR and Datamatrix

The Xcam camera system can be integrated into an existing Xtend3 system. A reliable mix-up control can thus be operated fully integrated from the central control. The camera reliably detects changes compared to the programmed product. Incorrect languages, make-ready sheets and deviations are detected with 100% accuracy and can be removed. Several Xcam functions can be displayed on the screen at the same time and thus be visually checked by the operator.

Xtend3 camera verification can perform accurate pattern recognition with Xcam PF AM / Xcam FS cameras. With the help of a contour comparison, illegible texts and graphics can also be programmed and then reliably compared and checked in the production process.

When checking blank sheets, a black and white contrast comparison is used to check whether double-sided printing has taken place. This is a reliable means of detecting whether there are missing or blank sheets in the stack. These are reliably ejected.

The Xtend3 camera verification performs flawless 1D / 2D code detection and reliably detects all common code formats such as EAN, Pharma, Interleaved, QR and Datamatrix

The Xcam camera system can be integrated into an existing Xtend3 system. A reliable mix-up control can thus be operated fully integrated from the central control. The camera reliably detects changes compared to the programmed product. Incorrect languages, make-ready sheets and deviations are detected with 100% accuracy and can be removed. Several Xcam functions can be displayed on the screen at the same time and thus be visually checked by the operator.

Xtend3 camera verification can perform accurate pattern recognition with Xcam PF AM / Xcam FS cameras. With the help of a contour comparison, illegible texts and graphics can also be programmed and then reliably compared and checked in the production process.

Zur Anzeige des Klick-Modells nutzen Sie gerne unsere Desktop-Version.

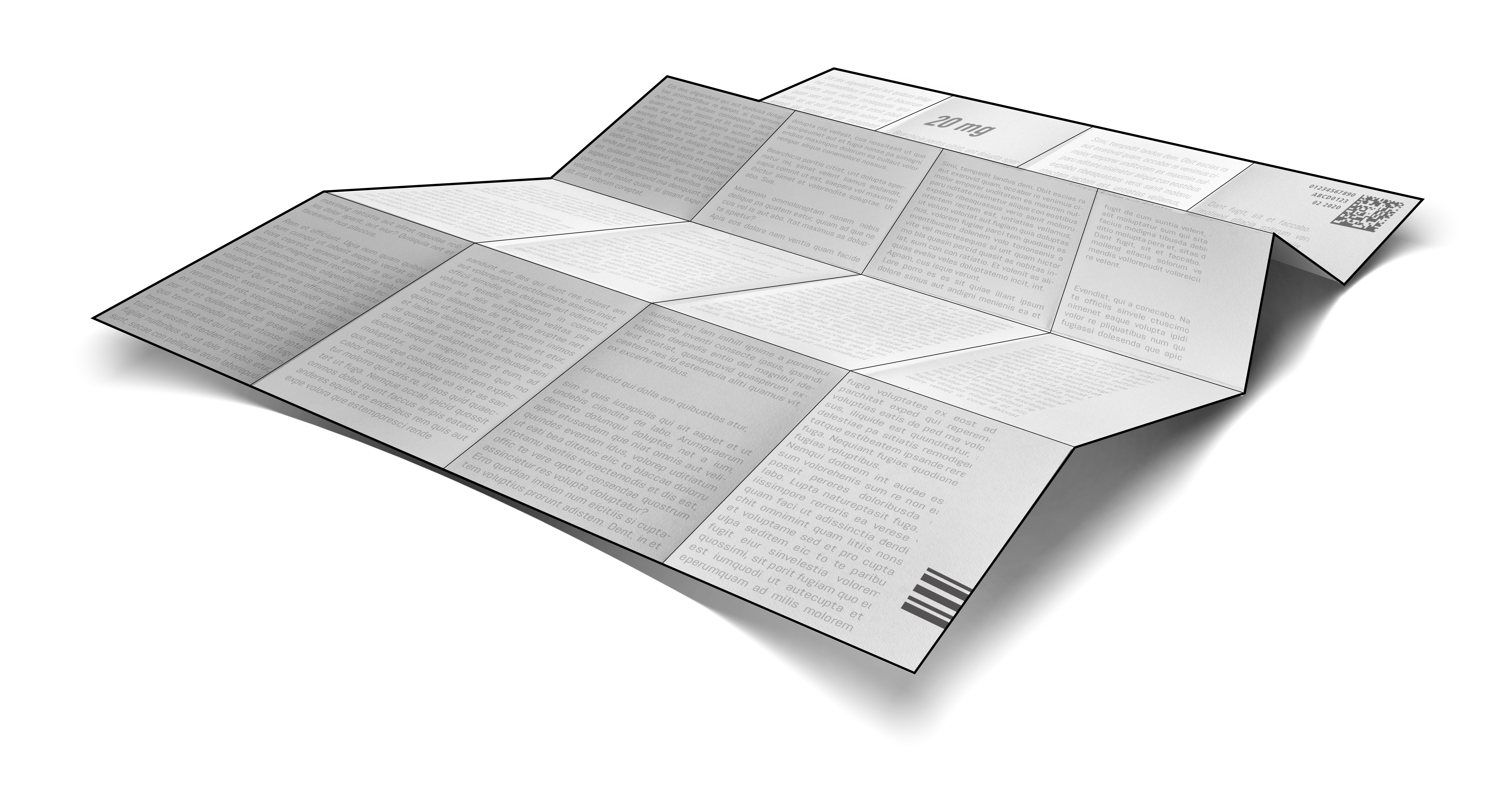

Booklet

In order to prevent the folded sheet of a booklet from opening in the saddle stitcher or the folded sheets from being displaced within a collated block, a very fine row of dots can be applied to the edge in the trim as auxiliary gluing. The bonding is removed with the end trim. With this form of application, booklets can be produced which are theoretically “impossible”.

V 500 - Precise cold glue application

V 500 - Precise cold glue application

Zur Anzeige des Klick-Modells nutzen Sie gerne unsere Desktop-Version.

Fold bonding

Baumer hhs electric cold glue valves apply adhesive quickly and precisely as dots and lines. In the production of fold-glued brochures, the adhesive is applied to the sheet with cold glue application heads, in dots or lines and without contact, before the first folding unit. After the last folding process and an optional head and foot trimming, you have a finished product without any further work steps.

V 500 - Precise cold glue application

Baumer hhs monitoring detects adhesive (cold glue or hot melt) on a wide variety of materials and evaluates the position and quality of the adhesive application. This system monitors adhesive on every product passing through the machine. Dot-by-dot at any speed. 100% safety.

V 500 - Precise cold glue application

Baumer hhs monitoring detects adhesive (cold glue or hot melt) on a wide variety of materials and evaluates the position and quality of the adhesive application. This system monitors adhesive on every product passing through the machine. Dot-by-dot at any speed. 100% safety.

Zur Anzeige des Klick-Modells nutzen Sie gerne unsere Desktop-Version.

Fold support

Waterscoring is specifically used for the production of supplements in the cosmetic and pharmaceutical industries. A mixture of water and alcohol, which reduces the restoring forces of the paper, is applied to the fold breaks before the folding process. The products lie much flatter, which makes processing easier in the packaging industry. Another positive aspect: more package inserts fit in the respective carton and the available packaging material is used more efficiently.

SW 600

SW 600

Zur Anzeige des Klick-Modells nutzen Sie gerne unsere Desktop-Version.

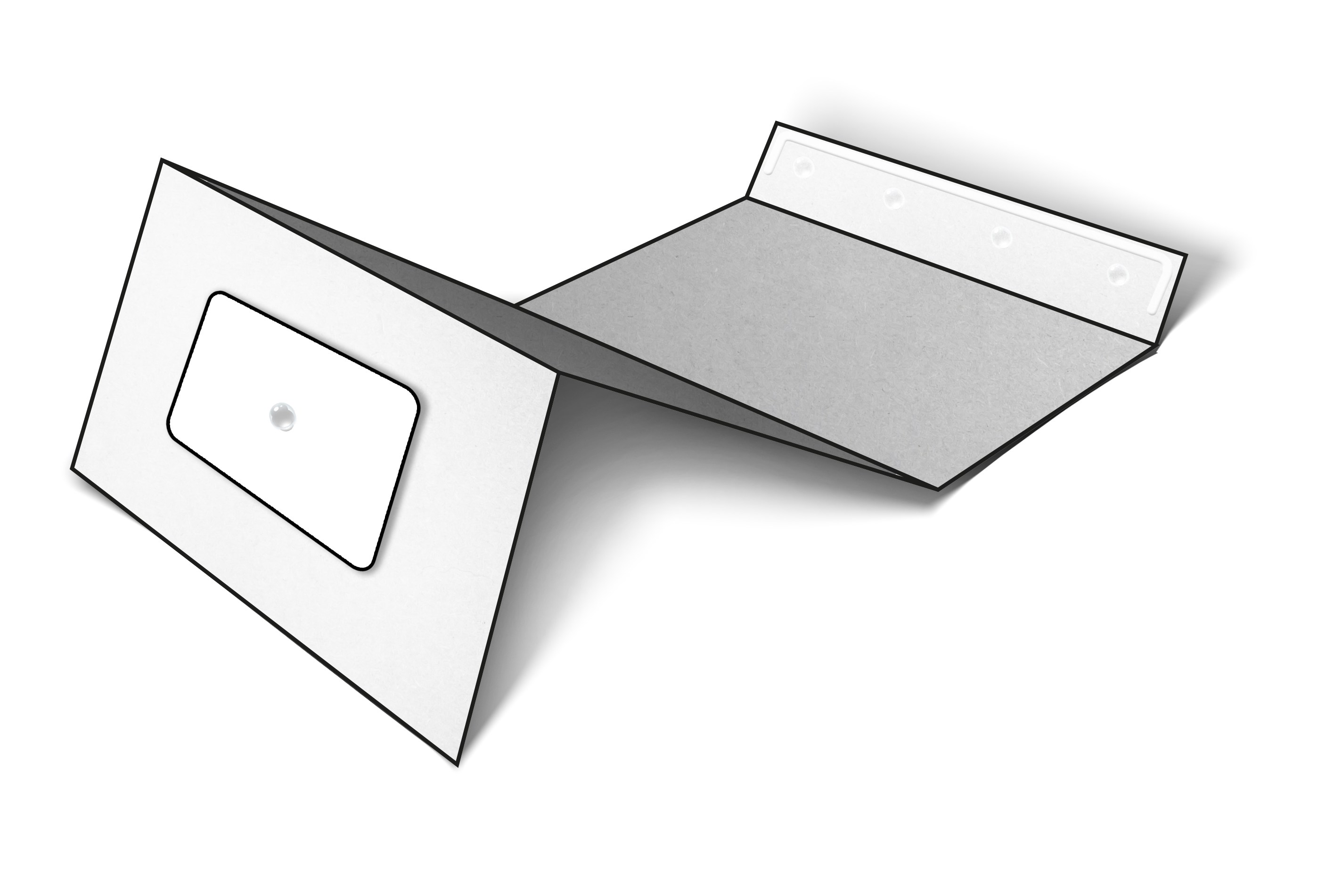

Package insert closure

Package inserts need to be securely closed for certain markets. Latex adhesive is used here to ensure that no fibers are torn out when the package insert is opened. This is the only way to ensure that all the necessary information is legible for the user. Latex adhesive is a cold glue that is applied with the precise, low-maintenance cold glue valves from Baumer hhs. Reliable and safe, in a quality that always meets and usually even exceeds the applicable regulations.

D 500 - Precise application of latex adhesives at all production speeds

D 500 - Precise application of latex adhesives at all production speeds

Zur Anzeige des Klick-Modells nutzen Sie gerne unsere Desktop-Version.

Mailings

Traditional mailings often consist of two parts: an information part and a reply part, on which a remoistenable gum has been applied using hot glue application. This reply part can be filled out, moistened, sealed and returned by the customer. Single track, U-gum and double U-gum linings can be applied to the sheet with a hot melt coating application head.

Closure of mailings with hot melt in coating or dot application. Fulfill the highest requirements of your customers!

- HP 500 F

So-called remoist U gum linings are used for mailings or other postal items: remoistenable adhesives allow you to create targeted adhesive bonds. With the HP-500 FR, hot melt coating applications up to 20 mm wide are possible and offer the flexibility you need!

- HP 500 FR

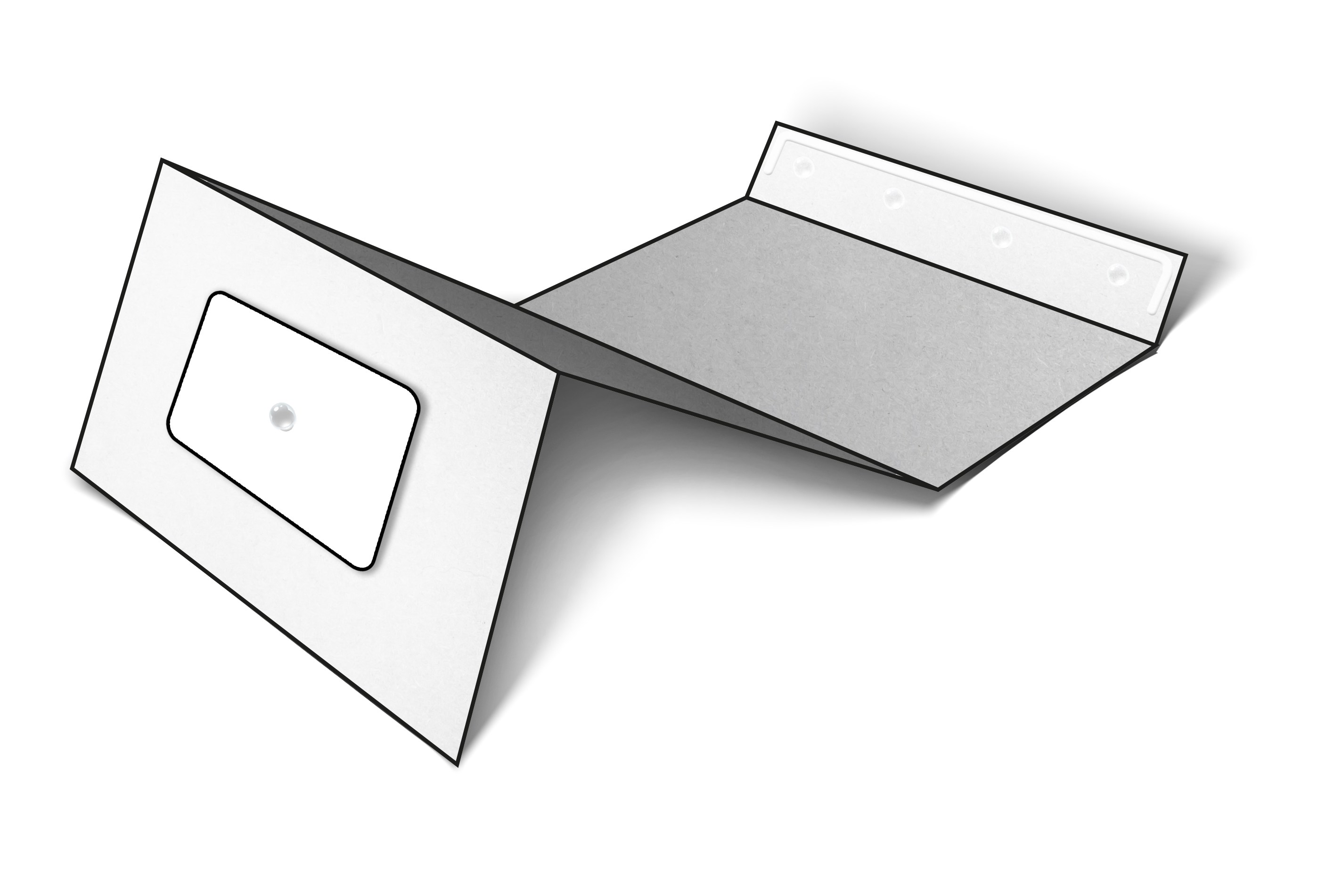

In a pick & place application, for example for the fixation of plastic cards or notices, a detachable hot melt is applied in dots to the carrier material, which fixes the product to be attached. This can then be detached from the carrier material again, without fibers tearing out. A film of hot melt applied to the surface can also be used to attach credit, customer or membership cards to letters.

- aerto hot melt valve

Closure of mailings with hot melt in coating or dot application. Fulfill the highest requirements of your customers!

- HP 500 F

So-called remoist U gum linings are used for mailings or other postal items: remoistenable adhesives allow you to create targeted adhesive bonds. With the HP-500 FR, hot melt coating applications up to 20 mm wide are possible and offer the flexibility you need!

- HP 500 FR

In a pick & place application, for example for the fixation of plastic cards or notices, a detachable hot melt is applied in dots to the carrier material, which fixes the product to be attached. This can then be detached from the carrier material again, without fibers tearing out. A film of hot melt applied to the surface can also be used to attach credit, customer or membership cards to letters.

- aerto hot melt valve

Zur Anzeige des Klick-Modells nutzen Sie gerne unsere Desktop-Version.

Sustainability

Resource-saving for more sustainability

Fast setup for less production waste

Minimization of cleaning cycles

Production waste reduction through quality assurance and product tracking

Developed for more production reliability

Fail-safe principle

100% quality control

Perfect adhesive application

Ensuring delivery quality

Safety

Package insert production in action!