Reinventing the Wheel: The Forgotten Art of Crease Moistening

Do you know the saying "reinventing the wheel"? That’s exactly how I feel when discussing moistening crease lines to improve foldability, prevent fishtailing, and stop the fold from cracking. All of these are proven benefits in packaging production—nothing new, just knowledge that seems to have been lost over the decades.

May I take you on a short but fascinating journey through the history of technology—back to the early 20th century, yet still close to the dawn of industrialized packaging production?

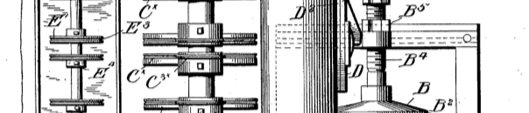

In 1901, the inventors Clayton and Jacob Wies developed a Box Tubing Machine for the production of matchboxes. For a long time, this remained an important segment in the packaging industry. The goal was to create a precisely shaped package with a minimal glue flap. Since hot-melt adhesive had not yet been invented, the glue flap also had to endure as little stress as possible.

This was achieved by using creasing wheels (marked as C in the upper drawing) to imprint fold lines onto the cardboard. These were then moistened by humidification wheels (E), which were aligned with the creasing wheels. The targeted moisture application, limited precisely to the fold edges, reduced bending stiffness and ensured a crack-free fold along the crease.

As so often, one idea sparks another. Ideas are the seedbed for new innovations. One invention rarely stands alone—it inspires, evolves, and gives rise to the next breakthrough.

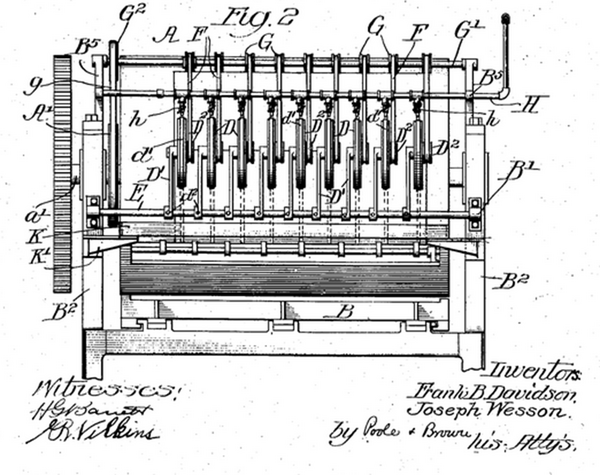

In 1905, inventors Frank Davidson and Joseph Wesson of the How and Davidson Company suggested moistening cardboard before it reached the creasing wheels.

The goal was clear: Moistening the material as a preparatory step before creasing the sheets along the fold lines. This was meant to prevent the creasing blades from excessively weakening the fibers, which could otherwise lead to material damage.

The invention highlights a specific issue: When using paperboard or strawboard, there was a risk that the creasing blades would break the fibers so severely that the sections along the fold lines would split apart. To prevent this, the inventors proposed targeted moistening of the narrow areas where the creasing blades would operate. This process softened the surface fibers, ensuring that the subsequent creasing operation did not cause damage.

The moistening device was designed to supplement a cutting and creasing press, typically consisting of a rotating impression cylinder and a corresponding plate. The moistening surfaces made direct contact with the sheets immediately before they were processed by the creasing blades, ensuring precise alignment between the moistened areas and the crease lines. The system could be adjusted to moisten all or only a selection of the intended crease lines, offering flexibility in production.

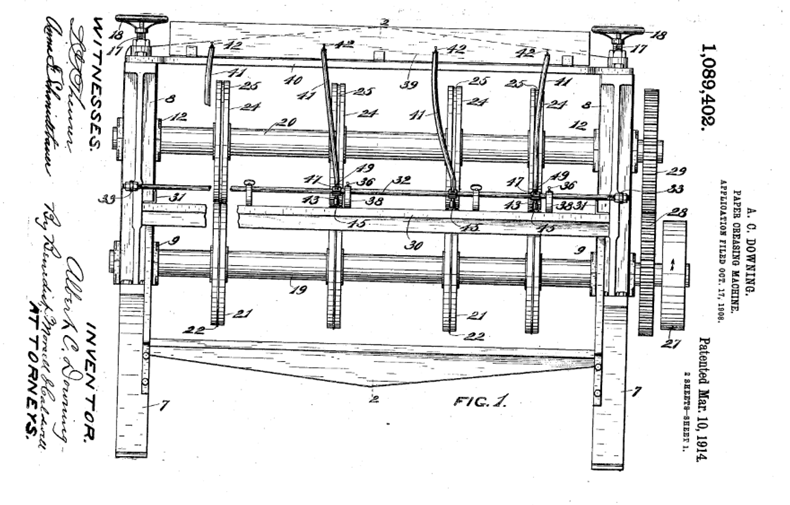

In 1914, Albert Dowing found that moistening crease areas with wheels was suboptimal. When crease wheels were used to apply moisture after the creasing process, they had to feature gaps to avoid deforming the creased lines. On the other hand, when moisture was applied before creasing, the creasing wheels had to be in direct contact with the substrate.

Now we know that cardboard and corrugated board are not always perfectly flat. This created a problem: Moisture wheels could leave unwanted impressions, and the amount of applied liquid varied depending on pressure and distance from the substrate.

To solve this, Albert Dowing developed a new approach: instead of using wheels, he proposed applying the moisture with nozzles directly onto the crease lines. This principle is still used today by Baumer hhs with its Waterscoring valves. The system sprays liquid across an air gap, ensuring that:

- The moisture transfer is precise and unaffected by surface irregularities.

- The substrate remains untouched by the moistening equipment, preventing unwanted marks or pressure variations.

This innovation significantly improved control and consistency in the creasing process—an approach that continues to shape modern packaging production.

It took some time for new ideas to emerge. In 1957, Swedish inventors Hall Knutson and Knut Folke introduced an innovative approach: combining crease moistening with adhesive reinforcement. Their goal was to ensure precise folding, prevent fiber breakage, and strengthen the packaging edges along the fold lines.

Their solution involved a moistening liquid containing alcohol, which allowed the water-based components to penetrate the cardboard quickly. This softened the substrate in the creasing and scoring areas, significantly reducing folding resistance.

The adhesive components in the liquid cured with a delay, reinforcing the weakened fold lines caused by creasing and softening. This method not only improved foldability but also enhanced Edgewise Compressive Strength (ECT), making the packaging more durable and resistant to pressure.

This clever combination of moisture and reinforcement marked an important step in packaging technology, balancing flexibility during folding with structural integrity.

In 1964, inventor Hugo Koran had a groundbreaking idea: applying the moistening liquid directly onto the creasing rollers using nozzles. To me, this remains the best approach, as the liquid is pressed into the substrate simultaneously with the creasing process. This ensures the moisture reaches precisely where it's needed, eliminating the risk of misalignment or the need for excessive application to cover the crease line reliably.

However, we soon realized a challenge: most modern creasing wheels are not corrosion-resistant. Ideally, they should be made of stainless steel or ceramic to withstand prolonged exposure to moisture.

To optimize the process, food-safe surfactants or alcohol can be added to ensure a uniform liquid spread across the roller surface.

If anyone has the opportunity to test this method, we are happy to provide precision equipment for fine-dosed application of the moistening liquid. This could be a game-changer for improving creasing quality and packaging durability.

As expected, machines kept getting faster, leaving less and less time for the moistening liquid to penetrate the substrate, especially in materials like corrugated board. The penetration speed depends largely on the capillarity of the substrate, its surface tension, and the surface tension of the moistening liquid.

For some substrates, distilled or osmosis water is sufficient to achieve fast penetration. However, for many materials, it is necessary to lower the surface tension of the moistening liquid below that of the substrate. This can be done by adding relatively high amounts of alcohol or small amounts of surfactants to the water.

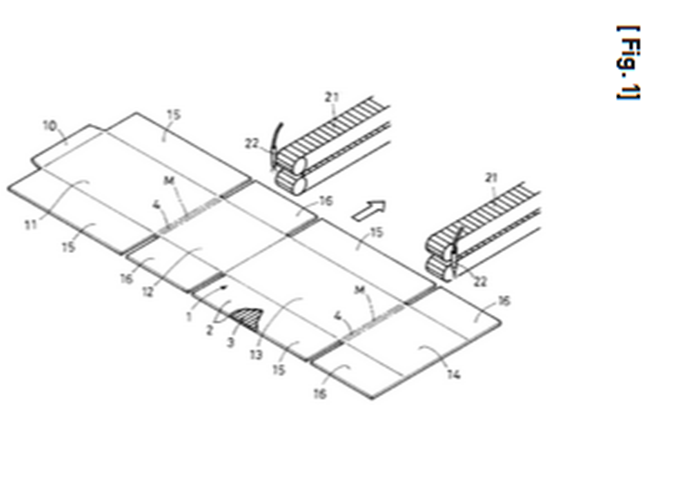

Recognizing this challenge, Japanese inventors KO IKEDA, MITSUO AKITANI, and KAZUO KIMURA from Rengo developed a solution: they added surfactants—referred to as "penetration agents"—to the moistening liquid.

Instead of using fast-evaporating alcohols, they introduced multi-chain alcohols, which evaporate more slowly, keeping the substrate moist for a longer period. This advancement ensured better control over moisture distribution, optimizing the creasing and folding process for high-speed packaging production.

I have deep respect for inventors, which is why the history of technology fascinates me so much. They had no AI to support their creative process—just brilliant minds, hands-on experimentation, and relentless determination.

In this sense, I am frustrated when solutions that were standard in the last century are now being reinvented and celebrated as world-first innovations.

If we look back to the early days of packaging production, we’ll find many ideas that are becoming relevant again—especially in the context of sustainability and design for recycling.

So let’s continue the work of our predecessors and refine their solutions. The knowledge is there—it’s up to us to apply it intelligently.

We are ready.

For more information on Baumer hhs Waterscoring applications, you can find details here:

Waterscoring_brochure_EN_LR.pdf

By

Thomas Walther

Corporate Strategy & Innovation Baumer hhs