Volume 02

Frauke von Knoop about corporate sustainability activities

Introducing Eco Talks

In our Eco Talks series, various people in management positions at Baumer hhs get an opportunity to share their personal insights on the subject of sustainability. In exclusive interviews, they shed light on Baumer hhs's past and ongoing steps to promote sustainability, and they explain exactly how our innovative solutions help customers to minimise their ecological footprint while making production processes more efficient. Eco Talks – Inspiring insight into sustainable innovation and responsibility.

In this episode, Plant Manager Dr. Frauke von Knoop talks with Florian Lemke (Digital Content Manager) about corporate sustainability activities of Baumer hhs.

Florian Lemke: Ms. von Knoop, sustainability is a major issue in many companies these days, but a lot of it is just talk. How serious is Baumer hhs about sustainability?

Frauke von Knoop: For us, sustainability is not just a regulatory requirement or a trend; it is a key component of our business strategy. At our sites in Krefeld and Berlin, we are implementing specific, eco-friendly measures to reduce our CO2 footprint, use resources efficiently, and make our products more sustainable. And our approach is holistic: We are not only optimising production systems, but also re-thinking social responsibility and supply chain sustainability.

Florian Lemke: That sounds ambitious. Let’s get into specifics: What are you doing at the production plant, for instance, to improve sustainability?

Frauke von Knoop: One illustrative example is our in-house recycling center, where all waste is separated, sorted, and the resulting raw materials recycled and reused. Products that have reached the end of their useful life are disassembled and the individual parts returned to the associated reusable material streams. In short, the recycling centre minimises waste and makes an important contribution to a circular economy.

Packaging is another target of our recycling efforts: Instead of using new material, we use recycled paperboard. For years now, we have also been collecting packaging from delivered goods. We shred it in a special process and use it as filling material for our own shipments.

Florian Lemke: A lot of companies talk about avoiding packaging waste. What practical steps has Baumer hhs taken to reduce it?

Frauke von Knoop: We have established a multi-trip packaging system with many of our suppliers. Today, some 50% of inbound deliveries arrive in reusable transport containers. The packaging materials are used multiple times instead of being discarded after a single use.

Florian Lemke: And what about outbound shipping?

Frauke von Knoop: Within Germany, we ship our products with DHL Green as another contribution to sustainability. This programme supports CO2 compensation projects worldwide.

Florian Lemke: What progress have you made in reducing CO₂ emissions? Have you reached any measurable milestones?

Frauke von Knoop: Yes we have! We have been systematically tracking our CO₂ footprint for the last three years and, in that time, have succeeded in reducing it significantly. For example, we cut our CO₂ emissions from 540t to 270t (scope 1+2) between 2021 and 2023. One main factor behind this achievement is that we use 100% green electricity.

But we have also optimised our energy consumption: By modifying the controller on our HVAC system, we have slashed power and heat consumption by over 20% over the last three years. We also conducted a survey of our employees to identify further saving potentials in the workplace. The results have led to added improvements and shown that a lot of small steps can have a big impact.

Florian Lemke: Those are interesting results. Can you give an example of how Baumer hhs is saving energy?

Frauke von Knoop: Gladly. One of the best examples is our intelligent lighting system. All of the old lamps at headquarters, inside and out, have been replaced with energy-efficient LEDs. Thanks to modern sensors, the lights only go on when really needed.

Florian Lemke: In other words, you are using not only green electricity, but also smart equipment to reduce consumption?

Frauke von Knoop: Exactly! We are looking at consumption from all sides and combining various methods to really cut down.

Florian Lemke: In many cases, sustainability also means changing employee behaviour. Are you taking action in this area?

Frauke von Knoop: We most certainly are! Eco-friendly mobility is another aspect that is very important to us. Our Job Bike programme, for instance, is a resounding success: Over 20% of our employees are already using this environmentally friendly alternative to commute to work.

Florian Lemke: Leaving their cars at home in favour of their bikes?

Frauke von Knoop: That’s right. Cycling reduces CO2 emissions and promotes the health of our employees. But of course we know that not everyone can cycle to work. It’s difficult for commuters who have to travel long distances. To include them in the programme, we have a recommended carpooling app. Co-workers can use it to find each other and drive to work together. Carpooling cuts personal fuel consumption, reduces traffic congestion, and decreases demand for parking space. As an added side-effect, it promotes a sense of community and belonging within the company.

Florian Lemke: So anyone who cannot switch to cycling still has a more sustainable alternative?

Frauke von Knoop: That’s right. And we have gone a step farther for eco-friendly mobility: In Krefeld, we use an electric vehicle to travel back-and-forth between our two sites. It minimises our CO2 footprint getting to the sites and is another building block in our strategy for promoting sustainable mobility.

Florian Lemke: Sustainability also impacts the supply chain. How does Baumer hhs ensure that the supply chain meets all requirements of environmental and social responsibility?

Frauke von Knoop: We have EcoVadis and tacto certification, proof positive that both Baumer hhs and its suppliers meet high environmental and social standards. Transparency is very important to us here, because our responsibility goes way beyond the limits of our own company. Like us, our customers are increasingly interested in responsible purchasing practices, and they frequently ask if we have the relevant certifications. We are able to assure them that we meet very high standards.

Florian Lemke: What about your products? Have you also considered their sustainability aspects?

Frauke von Knoop: Yes. We have had several of our developers trained as circular designers. They focus on designing products to be long-lived, repairable, and recyclable at the end of their useful life. In addition, all of our products meet the strict requirements of the RoHS and REACH directives, which ensure that they contain no hazardous substances.

Florian Lemke: And what about the administrative offices? Businesses tend to focus on production when it comes to sustainability.

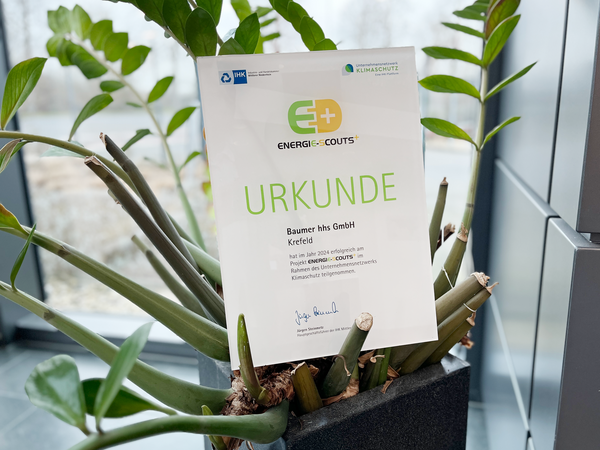

Frauke von Knoop: We are promoting environmental awareness in our administrative offices, too. One excellent example is our Energy Scouts programme. All of our vocational-technical trainees take a special class every year offered by the Chamber of Commerce and Industry to become certified Energy Scouts. They learn to identify energy saving potentials and develop suggestions for improving process efficiency. We are proud that our trainees are so proactive and offer their unique point of view.

Florian Lemke: What advantages does that have?

Frauke von Knoop: First, it sensitises the youngest members of our workforce at an early stage to the various aspects of sustainability. Second, they often come up with creative ideas for cost-saving measures, which we analyse and implement where effective.

Florian Lemke: How do you make sure your employees have the knowledge and skills they need to develop eco-friendly solutions?

Frauke von Knoop: We support training and continuing education for our employees in environmental occupations or so they can acquire the relevant qualifications. Our goal is to prepare our team as best we can, so they can actively participate in developing sustainable solutions in their areas. This is our way of ensuring that environmental awareness is anchored in our processes, but also in the expertise of our employees.

Florian Lemke: Sustainability has not only ecological, but also social components. Are you taking steps in this area as well?

Frauke von Knoop: Yes we are. We are proud to have received certification as a family friendly company for the second time. It demonstrates that, in addition to the environment, we also have our employees in mind.

Florian Lemke: And beyond these measures?

Frauke von Knoop: We support Villa Sonnenschein, a social services organisation for children with cancer and their families. Among other things, we sell used furniture and IT equipment to our employees and donate the proceeds to Villa Sonnenschein. The benefits are two-fold: we avoid unnecessary waste and support a good cause.

Florian Lemke: What a brilliant solution. Let’s talk about the subject of nature conservation. Is Baumer hhs active here, too?

Frauke von Knoop: On our company grounds in Berlin and Krefeld, we have installed various insect boxes and planted insect-friendly shrubs and tall grasses to create habitats for bees and other pollinators. So we are also contributing to species diversity.

Florian Lemke: Ms. von Knoop, I would like to conclude by asking: Is sustainability about meeting requirements for Baumer hhs, or is it a matter of course?

Frauke von Knoop: It’s a matter of course. We consider sustainability to be a continuous process and will continue to go in innovative directions to improve our environmental footprint, because taking responsibility for the future means making the right decisions today.

Florian Lemke: Thank you for talking with us!